Home>Products>Oil Production Line>50-100tpd cooking soybean oil automatic making mill machinery line

50-100tpd cooking soybean oil automatic making mill machinery line

- LD

Oil Production Line

- China

- ISO9001:2008 CE BV

- 1 Set/Sets

- US $28,000 - 1,000,000/ Set

- 15 days after confirmation the order

- paypal,UnionPay, Visa/MasterCard, Amex, Discover,T/T

- 50 Set/Sets per Month

-

Leader Machinery2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Leader Machinery2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Product Details

| Condition: | New | Usage: | Peanut Oil | Type: | Cold & Hot Pressing Machine |

| Automatic Grade: | Automatic | Production Capacity: | 5-1000 TPD | Place of Origin: | Henan, China (Mainland) |

| Brand Name: | Best | Model Number: | Best | Voltage: | 380v 440v |

| Power(W): | according the capacity | Dimension(L*W*H): | according the capacity | Weight: | according the capacity |

| Certification: | ISO9001 | After-sales Service Provided: | Overseas service center available | Name: | cooking soybean oil automatic making mill machinery line |

| Warranty: | 3 Years | Application range: | Plant Seed,stem,foliage | Supplier type: | factory |

| Advantage: | good quality equipment, high efficiency installation | supplier type: | factory |

Product Description

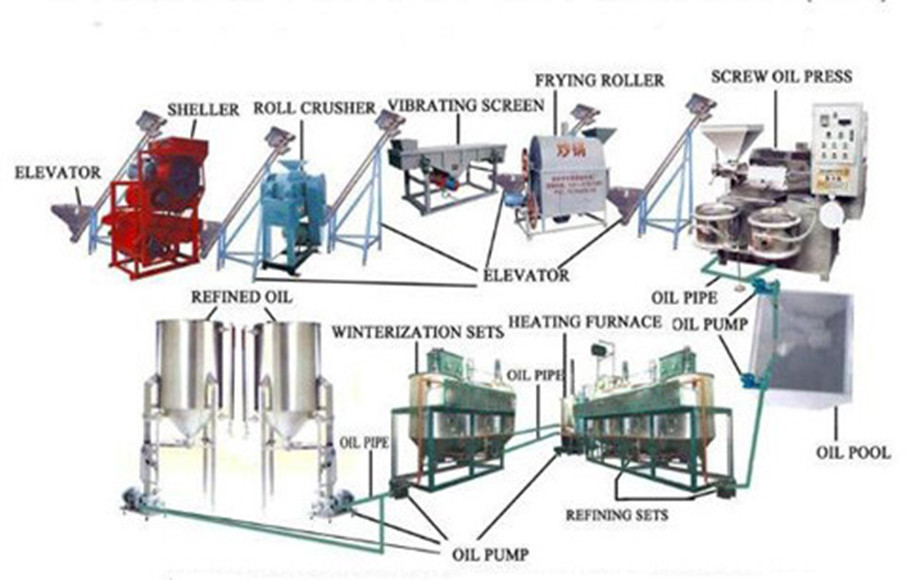

cooking soybean oil automatic making mill machinery line

Company InformationHenan Best Grain & Oil Machinery Engineering Co., Ltd. which specialize in producing edible oil mechanical equipment, a group enterprise integrating scientific research, manufacturing, sales as one . BEST has been undertaking more than 200 sets of oils and fats production turnkey projects . Our company has passed the international quality management system ISO 9001 and CE certificate. It has the qualification of manufacturing one or more types of pressure vessel .

Go with BEST, to be the best. Do what you think-BEST!

Product Description

cooking soybean oil automatic making mill machinery line

Best offer 5-30 tons of various oil pretreatment, leaching, squeezing engineering for you , Experienced technical personnel to provide first-class technology and mechanical design , From design (process, civil, electrical), manufacturing, installation, commissioning and after-sale full service, Advanced automation control system to ensure the whole production line of automatic and smooth running .

Pretreatment process feature

1.different combinations of process can process various oil plants in one workshop

2.Use special intensified pretreatment technology for aroma peanut oil to make it more aroma

3.Adopt advanced and reliable shelling technology to meet higher requirements for protein content meal

4.Extrusion treatment is use for raw materials with hard extraction,large-sized powder,and large capacity,which can reduce residual oil and solvent consumption,and increase the capacity by 50-80%

5.The new technology of shelling and low-temperature treatment can ensure high protein and least denaturation.

The establishment of oil pretreatment process , a variety of factors is oil varieties, take oil technology, product quality indicators, comprehensive utilization of oil , investment scale, So there are a number of alternative .Press process is relatively simple and can be based on the overall oil production process and product quality requirements, select press, pre-press, hot press, cold-pressed .

our advantages

(1) Professional technical team, provide strong support for the equipment manufacturing and installation.

(2) Equipment of the steel we choose SS/CS, has many years experience and very professional workers engaged in welding and assembly. Don't worry about the quality of the product.

(3) We have our own factory, there is no third party sales, so our price is lower.

Refining process

Degumming and deacidification: The gumming is moved by phosphoric acid and hot water. There are two ways to move the acid in the edible oil. One is chemical way, the other one is physical way.The chemical way is using NaOH to react with acid. This way is suitable for the capacity of 5-30T per day. The physical way is using steam and centrifugal to move the acid. This way is used for capacity from 30-2000T per day.

Decolorization: This step is used to adjust the color of the oil. You can control the color of the edible oil according to the requirement of your market.

Deodorization: The function of this step is to move the special smell in the oil. This is an important standard for refined edible oil.

Main business field

---10-500T/H oil material first cleaning,drying and storage section turn-key project.

---100-3000T/D oil pretreatment,shelling and pre-press wokshop trunkey project:rice bran production line turn-key project.

---100-300T/D leaching workshop trunkey project.

---30-1000T/D oil continuous grade oen or two physical(chemical)refining production line.

---20-3000T/D sunflower oil,corn germ oil dewaxing turn-key project.

---10-200T/D Fatty acid esterification production cooking oil production line.

Packaging & Shipping

Our Services

--- Ensure to timely provide complete sets of equipment and accessories.

---Ensure that one-time installation debugging acceptance.

--- To provide high quality material with preferential price.

---Free training technological operator to ensure the trained staff can operation independently

--we will offer an experienced project manager, organize a good installation team for the work of field installation debugging.

Warranty period: 2 years from the date you bought our machine.

The following situations are not included in our warranty.

(1) The damage which you did not according to our service manual.

(2) Normal spoilage of the quick-wear part.

(3) Someone who can’t use and maintain the oil press machine.

Whether the oil press machine is in our maintenance range or not, our after-sale service team all can help you to repair

Jinan Joysun Machinery Co., Ltd. professionnels de R & D de grains entiers, des équipements de raffinage de l'extraction du pétrole, du matériel de raffinage du pétrole partout dans le pays et exportés vers le Vietnam, l'Inde, la Russie, Hong Kong, Taiwan et d'autres endroits. Hong Renbing plus hospitalier pour « l'innovation scientifique, l'intégrité et durable, la qualité première, les services aux doués « philosophie d'entreprise, dédiée à vous fournir pratique, avec des prix compétitifs et de qualité et un service efficace 0,Jinan Joysun Machinery Co., Ltd. plate-forme de test disponible à tout moment Vous êtes invités à prendre les essais et discuter de la coopération!

machine de presse d'huile hydraulique, presse à huile hydraulique de sésame de rendement élevé d'huile 45kg, également connu sous le nom 50-100tpd cooking soybean oil automatic making mill machinery line, presse d'huile hydraulique, extrudeuse d'huile, moulin à huile, qui adopte le principe hydraulique pour produire l'huile comestible pure et assurée. L'ensemble du processus d'expulsion de l'huile de cuisson est visible et n'a besoin que d'environ 5-7 minutes; est tout à fait adapté aux ménages individuels et petites huileries à la campagne en raison de son peu d'occupation des chambres et la vitesse de pressage.Il est disponible au sésame, 50-100tpd cooking soybean oil automatic making mill machinery line noyaux de noix, graines de citrouille, graines de kiwi, graines de thé et amandes, etc.

Contact Us

- Leader Machinery

- Phone(Working Time)

Product Categories

- Flavor coating machine

- cold pressing oil machine

- biodiesel processing machine

- Bird food machine

- Corn flakes machine

- Dog food machine

- Oil Production Line

- animal oil processing equipment

- pet food extruder machine

- Bread crumbs making extruder processing line

- Puff rice snacks machine

- Core-filled snacks machine

- Oil refining equipment

- oil press machine

- fried chips machine

- Breakfast cereals extrusion line

- Cottonseed oil equipment

- japanese rice cake machine

- Soya meat extrusion line

New Products

2016 ISO:9001:2000 CE approved new type rice bran oil machine Crude oil refinery plant

2016 ISO:9001:2000 CE approved new type rice bran oil machine Crude oil refinery plant Full automatic peanut oil making machine

Full automatic peanut oil making machine Full automatic peanut oil press

Full automatic peanut oil press Rice Bran Oil Processing Plant,Rice Bran Oil Machine,Mini Rice Bran Oil Mill Plant

Rice Bran Oil Processing Plant,Rice Bran Oil Machine,Mini Rice Bran Oil Mill Plant China best supplier Rice Bran Oil processing plant machine oil production line

China best supplier Rice Bran Oil processing plant machine oil production line