Home>Products>Oil refining equipment>2013 Qie Equipment for Small Business at home

2013 Qie Equipment for Small Business at home

- LD

Oil refining equipment

- China

- CE, BV,ISO9001:2008

- One set 2013 Qie Equipment for Small Business at home

- Negotiation

- depend on the mode of the Equipment for Small Business at home

- Within 5 working days

- paypal,UnionPay, Visa/MasterCard, Amex, Discover,T/T

- 45

-

Leader Machinery2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Leader Machinery2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Product Description

2013 Qie Equipment for Small Business at home

(take the groundnut as an example)

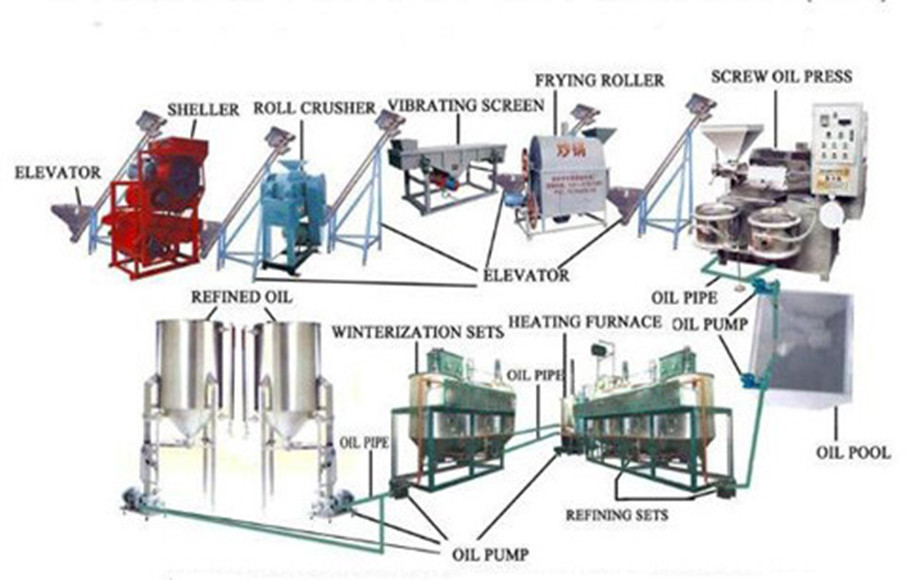

Pressing Process (oil seed crushing plant and pressing plant) Introduction:

High-quality groundnut→Cleaning→Crushing→Flaking→Cooking→

Pressing → Settlement→Crude oil

↓ ↑

Prepressed cake→ Secondary pressing→Extraction plant

Grade I oil can be achieved by this process

Oil Extraction Plant Introduction

Technical Process Introduction:

Flake→Extraction→Wet meal→Desolventizing→Cooling→Finished meal packaging

↓

Miscella→Filteration→2013 Qie Equipment for Small Business at home evaporation →Crude oil

↓

Solvent recovery

Features of Qi'E Rotocel Extraction:

a) Adopt stainless steel fixed grid plate and increase the horizontal grid plates, which can prevent the strong miscella from flowing back to the blanking case, so as to ensure good extraction effect;

b) The rotocel extractor is driven by rack, with unique rotor of balanced design, low rotating speed, low power, smooth operation, no noise and quite low maintenance cost;

c) The feeding system can adjust the rotating speed of airlock and main engine according to the feeding quantity and maintain a certain material level, which is beneficial to the micro negative pressure inside the extractor and reduce the solvent leakage.

d) The advanced miscella circulation process is designed to reduce the fresh solvent inputs, reduce the residual oil in meal, improve the miscella concentration and save energy by reducing the evaporation capacity.

e) The high material layer of the extractor helps to form immersion extraction, reduce the meal quality in miscella, improve the quality of crude oil and reduce the evaporation system scaling.

f) Specially suitable for the extraction of various pre-pressed meals.

Wet Meal Desolventizing Process:

Our company adopts the new high efficiency DTDC series desolventizer toaster.

Desolventizer toaster is the key equipment for wet meal desolventizing and passivation of anti-nutritional factors in the meal. which sets desolventizing, drying and cooling in one, with simple operation, stable product quality

Miscella Vacuum Evaporation Process:

The liquid from the extractor is the miscella containing grease and oil, which can be separated out according their different vaporization temperatures. Our company mainly uses 2013 Qie Equipment for Small Business at home evaporation technology, and it can reduce solvent leakage and consumption. The separated solvent vapour is cooled and recycled back to the extractor for reuse, which can improve the solvent efficiency.

Solvent condensation & recovery process:

Solvent condensation system combines with evaporation system closely, and evaporative condenser and steam stripping condenser all work under negative pressure. Non-condensable gas enters the energy saver from the shell of the first evaporator. In energy saver, non-condensable gas exchanges heat with condensate from the evaporative condenser. Finally, the condensate temperature discharged from energy saver is increased, and the solvent separated from water goes to solvent holding tank. The high temperature makes it unnecessary to be reheated for the recycling, so as to save energy.

Paraffin oil recovery process:

Tail gas first enters paraffin absorption tower, and then comes the counter-current absorption of paraffin and tail gas, which can reach the ideal state when the stainless steel packing has large surface area. The solvent content in discharged liquid paraffin (called rich oil) is not more than 5%, so as to ensure the maximum absorption rate

Oil Refining Workshop Exterior:

2013 Qie Equipment for Small Business at home drier: Dewater continuous 2013 Qie Equipment for Small Business at home drier with stainless padding has high drying efficiency;

Decolorizing tower: “Cycling evaporation stirred decolorizing tower” is used in bleaching section , which can save energy and reduce the leakage of 2013 Qie Equipment for Small Business at home due to machinery stirring.

Vertical leaf filter machine: Equipped with vertical leaf filter to remove used bentonite from the oil, operating conveniently and continuously , low laboring tense, keeps environment well, keeps oil residence in deposable bleaching earth in low level.

High efficient neutralization and deodorization system:

Deodorization is the key process to make high quality oil, the construction of deodorizer tower plays an important role. Our Deodorization tower has flash sector, holding sector, and high effective gentleness main de- odor sector which ensure high quality of oil. It combines with the function of FFA and odor compounds rapidly, makes good flavor for oil. Meanwhile, this tower has the advanta ge of lowering steam consuming of 30-50% than traditional tower and avoid of the hydrolyzation of oil;

Jinan Joysun Machinery Co., Ltd. est une grande entreprise par actions, axée sur la production d'2013 Qie Equipment for Small Business at home, intégrée à la recherche scientifique, à la production et aux ventes. La société est située dans la zone industrielle de Shandong salut-technologie, couvre une superficie de 50.000 mètres carrés, avec 15.000 mètres carrés deux standard usine industrielle lourde, plus de 160 ensembles toutes sortes de traitement des métaux de grande et moyenne taille, soudage, équipement d'assemblage .Jinan Joysun Machinery Co., Ltd. attache une grande importance aux échanges techniques et à la coopération internationale, a présenté la technologie de pointe sur et artisanat des États-Unis, Allemagne, Australie et autres pays, établit les lignes de production avancées internationales AAAA et base d'essai moderne de première classe.

Jinan Joysun Machinery Co., Ltd. basé sur une forte résistance technique, l'amélioration des méthodes de détection, excellent système d'assurance qualité pour assurer que « la qualité d'abord, le premier client », responsable de l'installation et la mise en service, les services techniques et des produits de formation technique, après l'installation est terminée je vais 9999999 techniciens vos opérations de production de l'entreprise du personnel de l'équipement de formation professionnelle et technique et des démonstrations en direct.

Contact Us

- Leader Machinery

- Phone(Working Time)

Product Categories

- Flavor coating machine

- cold pressing oil machine

- biodiesel processing machine

- Bird food machine

- Corn flakes machine

- Dog food machine

- Oil Production Line

- animal oil processing equipment

- pet food extruder machine

- Bread crumbs making extruder processing line

- Puff rice snacks machine

- Core-filled snacks machine

- Oil refining equipment

- oil press machine

- fried chips machine

- Breakfast cereals extrusion line

- Cottonseed oil equipment

- japanese rice cake machine

- Soya meat extrusion line

New Products

High Efficiency soybean crude oil refinery equipment

High Efficiency soybean crude oil refinery equipment 50t/d Crude oil refinery, oil extraction equipment for sunflower/peanut/cottonseed/flax oil

50t/d Crude oil refinery, oil extraction equipment for sunflower/peanut/cottonseed/flax oil modular refinery / crude oil refinery equipment / coconut oil refinery

modular refinery / crude oil refinery equipment / coconut oil refinery Mature technology waste essential oil processing refine unit

Mature technology waste essential oil processing refine unit energy saving soybean oil leaching equipment in 2016

energy saving soybean oil leaching equipment in 2016