Home>Products>Oil refining equipment>20-500TPD Rice Bran Oil Extraction Equipment in America and India with PLC

20-500TPD Rice Bran Oil Extraction Equipment in America and India with PLC

- LD

Oil refining equipment

- China

- ISO9001:2008&CE BV

- One set 20-500TPD Rice Bran Oil Extraction Equipment in America and India with PLC

- Negotiation

- depend on the mode of the rice bran oil extraction equipment

- Within 5 working days

- paypal,UnionPay, Visa/MasterCard, Amex, Discover,T/T

- 69

-

Leader Machinery2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Leader Machinery2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Product Description

20-500TPD Rice Bran Oil Extraction Equipment in America and India with PLC

Cathy wu

Mobile : 15938721580

Skype : cathy.wu666

20-500TPD Rice Bran Oil Extraction Equipment in America and India with PLC: cn1500376114

Simple Craft Flow Chart

Pretreatment and Press process:

Cleaning and separating----steaming----cooking----pressing----filter----crude oil

Each step purpose:

A, Cleaning and separating: Remove the broken rice and other impurities, that can guarantee the oil yield

B, Steaming: In order to soften the crude fibre and conglomerate the protein,break the cell wall,small oil drip can gather into the big oil drip, so that the oi can be easily out.

Condition: rotate speed: 40 temperature:80~100°C time:10min moisture:25~30%

C, Cooking: lower the moisture in the rice bran, so that oil can be easily out,

Condition: stir constantly.temperature:125°C,time:20~30min,moisture lower to:5~7%.

D, Press condition: temperature:80~90°Ctime:3~5min

E, Filter condition: temperature: 70°C

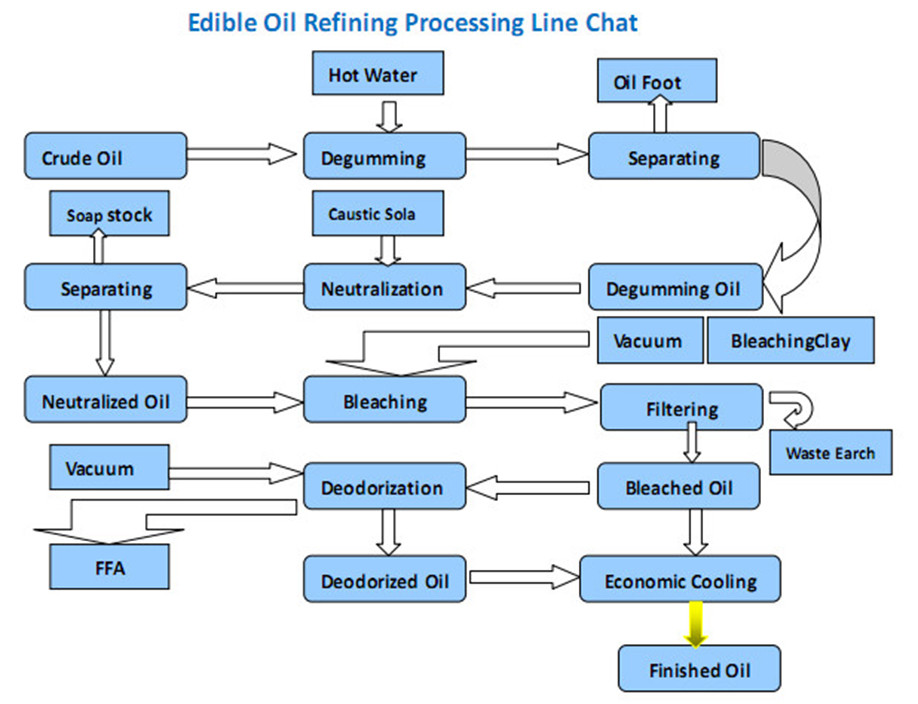

Refining process:

Crude oil----degumming----deacidification----decoloring----filter----deodorizing----fourth grade oil

Crude oil----degumming----deacidification----decoloring----filter----deodorizing----dewaxing----degrease----first grade oil

Four grades oil in China Standard

Introduction of Rice Oil Making Craft in Detail

Cleaning and Separating:

This process mainly to remove the impurities like iron,sand,broken rice and others. If the impurities exist in the rice bran, it will affect the machines operation. And make the crude oil impure,then largely affect the refining process.

The cleaning method mainly includes screen and magnetic separation.

Steaming:

This process namely soften the rice bran,making the bran cooked.as the rice bran is low oil content and low moisture content, so it has to through steaming to adjust its moisture and temperature to a suitable level, that can increase the rice bran elastic-plastic. break the cell wall and oil easily out when pressing.

Cooking:

This process has the same purpose with steaming, aiming to make the oil out easily, the difference is just lower the moisture to 5~7%,to much water content will affect the oil outing.

Pressing:

This is the oil out process, the cooked rice bran will be sent to screw oil press machine through the screw conveyor. After pressing, we can get the crude rice bran oil.

Filter:

Filter the crude oil with canvas or double layer cloth in the Plate-fram filter, control the temperature to 70°C,then the crude oil will be sent to the refining process.

Refining Plant:

Phosphoric acid alkali clay 20-500TPD Rice Bran Oil Extraction Equipment in America and India with PLC

↓ ↓ ↓ ↓

Crude oil---- degumming ----deacidification ----decoloring ----deodorizing ----fourth grade oil

↓ ↓ ↓ ↓

Oil sediment soapstock Clay residue waste gas

Introduction of the whole process:

A,First send the crude oil into the mix reactor with certain quantity water and acid, after well blended send into the centrifugal separator and then separate the oil sediment.

B,Second send into another mix reactor, adding certain concentration alkali and well neutralization reaction. Separate the soapstock through the centrifugal separator.

C,Now wash the crude oil with light alkali and water, washing out the residual soapstock.

D,Third send the oil into the bleaching tower,well blended with certain quantity clay, under the certain temperature,time,20-500TPD Rice Bran Oil Extraction Equipment in America and India with PLC condition, the clay absorb the colorful substance and other impurities. Then separating the waste clay through the centrifugal separator.

E,At last send the oil into deodorization tower,under the certain temperature and 20-500TPD Rice Bran Oil Extraction Equipment in America and India with PLC condition, deodorizing the oil through steam stripping. Then get the fourth grade oil.

Our machines advantages:

1,some of our technology adopts Germany standard, and some equipment parts are imported.

2,our stainless steel and carbon steel are all purchased directly from the steel factory.our professional engineer will detect every time.so we can guarantee the quality.

3,all of our welding technicians have the employment certificates.they are good at it.

4,we provide installation and professional training.

5,we supply the best service to our customer,if there is any technology problem,we will transfer it to our customer.

Professional suggestion:

Kindly please inform us your required daily capacity, quantity, raw material, covering space and related data,

so that we can provide you professional equipment information and design proper oil production line for you. we will suggest economical and reasonable production line for you.

Jinan Joysun Machinery Co., Ltd. est une grande entreprise par actions, axée sur la production d'20-500TPD Rice Bran Oil Extraction Equipment in America and India with PLC, intégrée à la recherche scientifique, à la production et aux ventes. La société est située dans la zone industrielle de Shandong salut-technologie, couvre une superficie de 50.000 mètres carrés, avec 15.000 mètres carrés deux standard usine industrielle lourde, plus de 160 ensembles toutes sortes de traitement des métaux de grande et moyenne taille, soudage, équipement d'assemblage .Jinan Joysun Machinery Co., Ltd. attache une grande importance aux échanges techniques et à la coopération internationale, a présenté la technologie de pointe sur et artisanat des États-Unis, Allemagne, Australie et autres pays, établit les lignes de production avancées internationales AAAA et base d'essai moderne de première classe.

Jinan Joysun Machinery Co., Ltd. basé sur une forte résistance technique, l'amélioration des méthodes de détection, excellent système d'assurance qualité pour assurer que « la qualité d'abord, le premier client », responsable de l'installation et la mise en service, les services techniques et des produits de formation technique, après l'installation est terminée je vais 9999999 techniciens vos opérations de production de l'entreprise du personnel de l'équipement de formation professionnelle et technique et des démonstrations en direct.

Contact Us

- Leader Machinery

- Phone(Working Time)

Product Categories

- Flavor coating machine

- cold pressing oil machine

- biodiesel processing machine

- Bird food machine

- Corn flakes machine

- Dog food machine

- Oil Production Line

- animal oil processing equipment

- pet food extruder machine

- Bread crumbs making extruder processing line

- Puff rice snacks machine

- Core-filled snacks machine

- Oil refining equipment

- oil press machine

- fried chips machine

- Breakfast cereals extrusion line

- Cottonseed oil equipment

- japanese rice cake machine

- Soya meat extrusion line

New Products

High Efficiency soybean crude oil refinery equipment

High Efficiency soybean crude oil refinery equipment 50t/d Crude oil refinery, oil extraction equipment for sunflower/peanut/cottonseed/flax oil

50t/d Crude oil refinery, oil extraction equipment for sunflower/peanut/cottonseed/flax oil modular refinery / crude oil refinery equipment / coconut oil refinery

modular refinery / crude oil refinery equipment / coconut oil refinery Mature technology waste essential oil processing refine unit

Mature technology waste essential oil processing refine unit energy saving soybean oil leaching equipment in 2016

energy saving soybean oil leaching equipment in 2016