Home>Products>Puff rice snacks machine>Corn puffed cheese stick /ball production line

Corn puffed cheese stick /ball production line

- LD

Puff rice snacks machine

- China

- CE

- One set Corn puffed cheese stick /ball production line

- Negotiation

- 17100 *3000*3000 mm

- Within 5 working days

- paypal,UnionPay, Visa/MasterCard, Amex, Discover,T/T

- 109

-

Leader Machinery2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Leader Machinery2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Product Description

Product Description

I. Corn puff snacks production line corn extruder

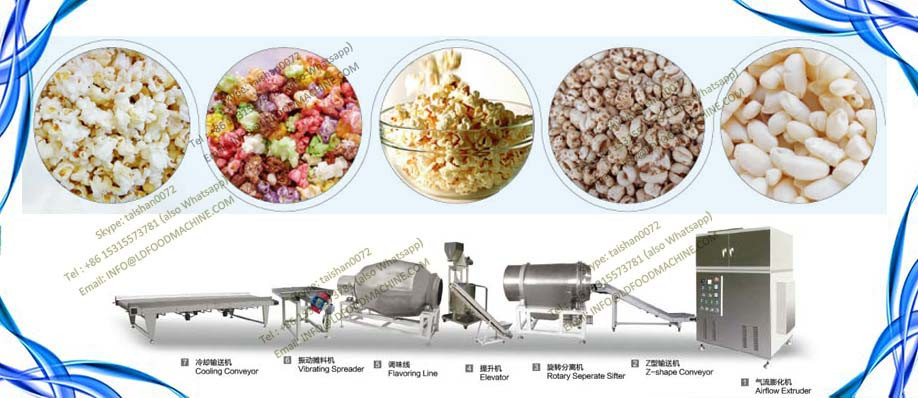

This corn puff snacks production line is applied to make directly puffed / extruded snacks with different shapes , the main raw material is corn flour ,wheat flour, rice flour and so on . With core filling machines and the shapers , you can also make core-filling snacks with this production line

A typical co-extrusion processing line includes mixing and oil spraying systems, a twin-screw extruder at the heart of the process and shaping equipment. Drying, coating and cooling devices are then used accordingly.

Extruded flakes can also be made on the same lines with complementary equipment.

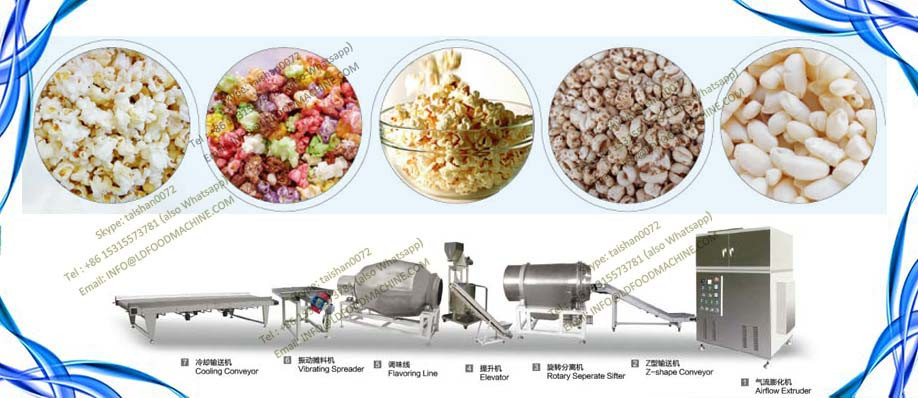

II. Machine list of puff corn snacks production line

1. Mixer : mix the raw material equally

2. Conveyor : take the raw material to the extruder

3. Extruder : to cook the raw material with high temp and pressure to make them puffed

4. Injector : inject chocolate / jam/ butter to the center of the snacks

5. Cutter : Cut the core-filled snacks into certain length

6. Elevator : take the snacks to the oven

7. Oven : Bake the snacks to be crispy

8. Flavoring line : Spray oil and powder type seasonings to make different flavors

III. Raw material : corn flour, wheat flour , rice flour

IV. Flavoring material : sugar powder , caramel , cream , food oil , chilly powder and so on

V. Heating source of oven : Electricity , gas or deisel

VI. Machine power supply : electricity

corn puff snacks processing line

| Model | Capacity | Installed power | Dimension |

| DG65-II | 100~150 kg/h | 52kw | 22600×3000×2500mm |

| DG70-II | 200~300 kg/h | 86kw | 24000×3000×2500mm |

| DG75-II | 300~350 kg/h | 116kw | 26000×2500×2500mm |

| DG85-IV | 400~600 kg/h | 141 kw | 27300×3000×2500mm |

Different shapes of puff snacks such as tube, ball ,star, ,heart ring and so on , can be made by the same production line , you will only need to change the dies and cutting machines .

Why choose us

Why choose us1.Something about Puff rice snacks machine Machinery Co., Ltd

Established in the year of 2012 , a professional team with more than 20 years experience in the extrusion system industry , Puff rice snacks machine Machinery Co., Ltd grows very fast in 3 years, to becoming a Corn puffed cheese stick /ball production line manufacturer in Chine Extrusion System Industry .

We are the FIRST manufacturer in China for the hot air puffing system and the advanced EU type extrusion system, our machines are machine getting popular all over the world , we have sold the production lines to America, Australia, Canada , Italy, Japan, Jordan, Saudi Arabia, Thailand ,Malaysia , Russia, Slovakia, Turkey,Uzbekistan, India, Pakistan and so on .

2.What is the advantage of your puff snacks making machines ?

We have different series of twin screw extruder for making puff snacks .

The traditional type extruder : DG65-III DG70-II DG85-IV

We also have Advanced type extruder : DG52-II DG75-II DG95-II

4. Which famous brand of parts we use for the corn puff snacks machine extruder ?

Machine shield : 201 ss / 304 ss as required

Parts contact with food : 201 ss / 304 ss as required

Main motor: Corn puffed cheese stick /ball production line brand

Touch screen : Wenview brand

Miniature circuit breaker : ABB brand

Alternating current contactor: ABB brand

Thermal Relay: ABB brand

Moulded case circuit brake : CHNT brand

Small relay: Weidmuller brand

Inverter: Delta brand

PLC system: Delta brand

Burner: Baltur brand

Bearing : NSK/ SKF brand

More information

More informationMore video information of bugle chips making machine will be provided , too

Other popular production line. Click the item to see more information

1. Breakfast cereal corn flakes making machine

2. Corn puff snacks production line

3. 2D/ 3D wheat snack pellets production line

4.. Fired bugle chips snack processing line

5. Soya protein products making machine

| Packaging | |

| Item | CORN FLAKES MAKING MAHCINE |

| Weight | 100~4000 KG |

| Packaging Details |

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

| Packaging | |

| Size | CORN FLAKES MAKING MAHCINE |

| Weight | 100~4000 KG |

| Packaging Details |

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

More video information of bugle chips making machine will be provided , too

Other popular production line. Click the item to see more information

1. Breakfast cereal corn flakes making machine

2. Corn puff snacks production line

3. 2D/ 3D wheat snack pellets production line

4.. Fired bugle chips snack processing line

5. Soya protein products making machine

Jinan Joysun Machinery Co., Ltd. professionnels de R & D de grains entiers, des équipements de raffinage de l'extraction du pétrole, du matériel de raffinage du pétrole partout dans le pays et exportés vers le Vietnam, l'Inde, la Russie, Hong Kong, Taiwan et d'autres endroits. Hong Renbing plus hospitalier pour « l'innovation scientifique, l'intégrité et durable, la qualité première, les services aux doués « philosophie d'entreprise, dédiée à vous fournir pratique, avec des prix compétitifs et de qualité et un service efficace 0,Jinan Joysun Machinery Co., Ltd. plate-forme de test disponible à tout moment Vous êtes invités à prendre les essais et discuter de la coopération!

Jinan Joysun Machinery Co., Ltd. par l'innovation et efforçons l'excellence en ressources humaines, la technologie, les produits et services, et d'améliorer constamment le niveau de service à l'acheteur, avec une forte, ciblée et efficace d'améliorer la satisfaction de l'acheteur. "Intégrité, excellence, équipe, responsabilité" est la valeur de notre entreprise, est le facteur clé dans le succès de la formation du personnel.

Contact Us

- Leader Machinery

- Phone(Working Time)

Product Categories

- Flavor coating machine

- cold pressing oil machine

- biodiesel processing machine

- Bird food machine

- Corn flakes machine

- Dog food machine

- Oil Production Line

- animal oil processing equipment

- pet food extruder machine

- Bread crumbs making extruder processing line

- Puff rice snacks machine

- Core-filled snacks machine

- Oil refining equipment

- oil press machine

- fried chips machine

- Breakfast cereals extrusion line

- Cottonseed oil equipment

- japanese rice cake machine

- Soya meat extrusion line

equipment for peanut flip

equipment for peanut flip Cheez Doodles extruder

Cheez Doodles extruder bread croutons mini bread process equipment

bread croutons mini bread process equipment Puffing rice corn puffs snacks food making extruder line

Puffing rice corn puffs snacks food making extruder line Puffs ring snack food production extruder equipment

Puffs ring snack food production extruder equipment