Home>Products>Bread crumbs making extruder processing line>Automatic Dry bread crumbs machinery plant

Automatic Dry bread crumbs machinery plant

- LD

Bread crumbs making extruder processing line

- China

- TUV CE

- One set Automatic Dry bread crumbs machinery plant

- Negotiation

- 3*1*0.8m

- Within 5 working days

- paypal,UnionPay, Visa/MasterCard, Amex, Discover,T/T

- 69

-

Leader Machinery2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Leader Machinery2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Product Description

Automatic Dry bread crumbs machinery plant

Product Description of Automatic Dry bread crumbs machinery plant

1.Bread crumbs are widely used to coat the surface of fried food as a food additive. Such as fried chicken, drumstick, shrimp, onion rings, etc.

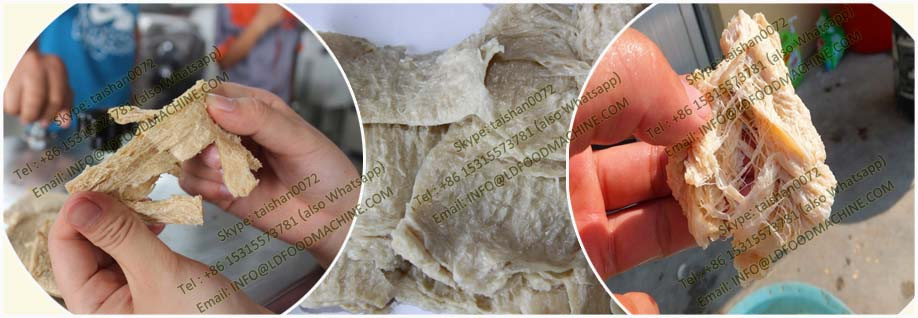

The long and sliver shaped breadcrumbs are of porous structure inside.

After frying, the crumbs become straight up bit by bit. They are not only puffed and nice in appearance but also crisp and delicate in taste.

2. Bread Crumbs Production Line Making manufacturers Machine is specially designed and developed according to market demand.

The whole line can be finished from the raw materials, extrusion, drying to finished products automatically.

A . Production line details of Automatic Dry bread crumbs machinery plant

Capacity |

120kg-1000kg |

Power Supply |

Based on 380V 50 Hz 3 phase. Customized according to your local power. |

Machine details |

1.Stainless steel,:201, 304, 316, on request 2. Electric parts can be ABB, Delta, Fuji, Omron, Automatic Dry bread crumbs machinery plant; Famous brand as your demand. |

Certificate |

CE,GOST,TUV,BV |

Raw Material |

Wheat flour, etc. |

Products Color |

White, Yellow |

Products type |

Particle, needle etc. |

B. Advantages of Automatic Dry bread crumbs machinery plant

1.The screw material: Alloy steel (38CrMoAL) by nitriding process. High strength and wear-resting.

With good self-cleaning ability, it’s unnecessary to remove the barrel and screws for cleaning.

2.SIMENS (China) Motor

3.It adopts speed-adjusted converter on feeding system, extrusion system and cutting system.

Food grade stainless steel twin screw feeding device guarantees stable materials feeding in the whole food process.

4. Adopted the Delta inverters, ensure the extruder better running.

5. The gearbox has automatic lubrication function, which prolong service life of gears.

6. Cutting knife is fixed in the die head seat, rotary cutting driven by V-belt.

C .Technical Parameters of Automatic Dry bread crumbs machinery plant

Model |

Installed power |

Real power |

Capacity |

Dimension |

ZH65 |

45kw |

22kw |

120-150kg/h |

39000x1200x2200mm |

ZH70 |

50kw |

37kw |

280-320kg/h |

41000x1500x2200mm |

ZH85 |

110kw |

75kw |

450-550kg/h |

43000x3500x4300mm |

ZH95 |

151kw |

110kw |

850-1000 kg/h |

4700x1900x4800mm |

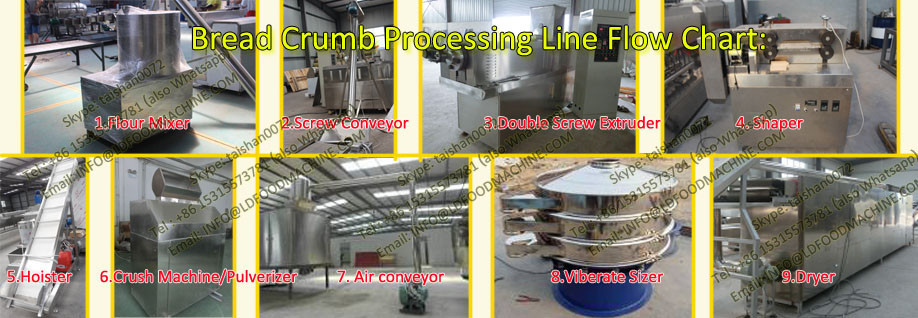

D.Production process of Automatic Dry bread crumbs machinery plant

Mixing Raw material -----Extruding----Drying--- Crushing---Screening---Packing

Packing: Automatic Dry bread crumbs machinery plant for Onion Ring Bread Crumb are always wrapped by film completely and safely and then packed in strong fumigation-free case or 20'/40' container for delivery.

We take good care of each machine for you

Delivery: 20-30 days after receiving advance payment.

| Pre-sale service |

Communicating with customers and learn your requirement |

| Providing professional advisory services | |

|

Providing solutions according to customers’ requirement, And offer the quotation | |

| Providing on-site visit to our factory | |

| Providing samples | |

| Selling service |

Confirm every terms and details and sign contract with customers |

| Manufacturing machines according to contract. | |

| Trial running after production. | |

| Packing machines and delivery on time | |

| Providing relevant documents for Custom clearance(If necessary) | |

| After-sale service | Send engineers for installation, trial running and training workers. |

| Handling the problems occurred during use. | |

| Supply spare and wearing parts on discount. | |

| Help customers to solve any other problems |

1.Are you a manufacturer or a trading company?

We are a professional manufacturer of food & feed extrusion machine

2.What's the price of your machines?

You can inquiry to us directly

3.What is your payment terms?

Recommend to use Automatic Dry bread crumbs machinery plant’s Trade Assurance.

T/T or L/C; by T/T 30% as down payment, 70% by T/T before delivery, L/C before shipment.

4. Can we provide the formula to you?

We can provide basic formula for producing the food etc.

And help customer to produce good quality food according customer’s detailed formula.

5. What is the workshop size required?

The production line can be put in straight line and also can change the direction according to your factory size.

We can design the layout according to your factory size.

Jinan Joysun Machinery Co., Ltd. est une grande entreprise par actions, axée sur la production d'Automatic Dry bread crumbs machinery plant, intégrée à la recherche scientifique, à la production et aux ventes. La société est située dans la zone industrielle de Shandong salut-technologie, couvre une superficie de 50.000 mètres carrés, avec 15.000 mètres carrés deux standard usine industrielle lourde, plus de 160 ensembles toutes sortes de traitement des métaux de grande et moyenne taille, soudage, équipement d'assemblage .Jinan Joysun Machinery Co., Ltd. attache une grande importance aux échanges techniques et à la coopération internationale, a présenté la technologie de pointe sur et artisanat des États-Unis, Allemagne, Australie et autres pays, établit les lignes de production avancées internationales AAAA et base d'essai moderne de première classe.

Jinan Joysun Machinery Co., Ltd. basé sur une forte résistance technique, l'amélioration des méthodes de détection, excellent système d'assurance qualité pour assurer que « la qualité d'abord, le premier client », responsable de l'installation et la mise en service, les services techniques et des produits de formation technique, après l'installation est terminée je vais 9999999 techniciens vos opérations de production de l'entreprise du personnel de l'équipement de formation professionnelle et technique et des démonstrations en direct.

Contact Us

- Leader Machinery

- Phone(Working Time)

Product Categories

- Flavor coating machine

- cold pressing oil machine

- biodiesel processing machine

- Bird food machine

- Corn flakes machine

- Dog food machine

- Oil Production Line

- animal oil processing equipment

- pet food extruder machine

- Bread crumbs making extruder processing line

- Puff rice snacks machine

- Core-filled snacks machine

- Oil refining equipment

- oil press machine

- fried chips machine

- Breakfast cereals extrusion line

- Cottonseed oil equipment

- japanese rice cake machine

- Soya meat extrusion line

powerful and useful dry bread crumb production line

powerful and useful dry bread crumb production line bread crumbs making machine production line

bread crumbs making machine production line automatic panko bread crumbs powder making equipment

automatic panko bread crumbs powder making equipment panko bread crumb process line extruder

panko bread crumb process line extruder panko bread crumbs machines maker process line

panko bread crumbs machines maker process line