Home>Products>Oil refining equipment>Waste Engine Oil Distillation Column Oil Refinery Equipment

Waste Engine Oil Distillation Column Oil Refinery Equipment

- LD

Oil refining equipment

- China

- ISO9001:2008;CE

- One set Waste Engine Oil Distillation Column Oil Refinery Equipment

- Negotiation

- as different capacity

- Within 5 working days

- paypal,UnionPay, Visa/MasterCard, Amex, Discover,T/T

- 122

-

Leader Machinery2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Leader Machinery2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Product Description

Waste Engine Oil Distillation Column Oil Refinery Equipment

Proction Description

Item |

Used Oil Distillation to Base Oil Equipment |

Model |

DIR model |

Principle |

pysical-chemical reaction |

Capacity |

1,000Liters per day to 30,000Lites per day |

Material |

Stainless steel and carbon steel |

Function |

remove carbon contamination,dirty colloid,metal particles, gas, water, change black color to golden yellow |

|

Oil Material

|

Used diesel and gasoline enging oil, car oil, motor oil,transmission oil, hydraulic oil etc.

|

|

Recycled oil

|

Yellow base oil,SN150-SN300

|

|

Oil yield rate

|

80%-85%

|

Thickness of distillation kettle |

14mm |

|

Space required

|

300-400 sq.m., the bigger, the better

|

working pressure |

20-50pa |

Working temperature |

300degree |

Heating method |

Thermal Fuel Boiler(customer self-provide) or electricity heating. |

Recycled oil |

Yellow base oil,SN150-SN300 |

recycled oil color |

No.1-1.5 |

Viscosity index |

96 |

Flash point(open) |

225-230degree |

Viscosity(40C)mm2/S |

50 |

What can we get from DIRseries waste engine oil distillation machine?

It is mainly used to change waste oil into clean base oil. The final base oil will be SN150, SN250, SN300. The base oil can be used as the raw materials of kinds of usable oil, such as new engine oil, new motor oil, new lubricant oil and so on.

You can build one production line for waste oil into new engine oil, or you can sell the base oil to other oil manufacturers directly.

Main Features of DIR Waste Oil Distillation Plant:

1. Easy to operate, low operation cost

2. Environmentally friendly, without secondary pollution.

3. The machine can recycle gasoline oil, diesel oil, engine oil, rubber oil and other lubricant oil to clean oil.

4. High quality refined oil, no any discoloration caused by oxidation, no any bad smelling.

5. Low cost contain:

1) only need the catalyst chemical, the cost is less thanUS$30 to refine one ton waste oil.

2) Heat consumption: 105kcal per ton waste oil

3) Power consumption: 40Kwh to recycle 1 ton waste oil

6. High degree of automation.

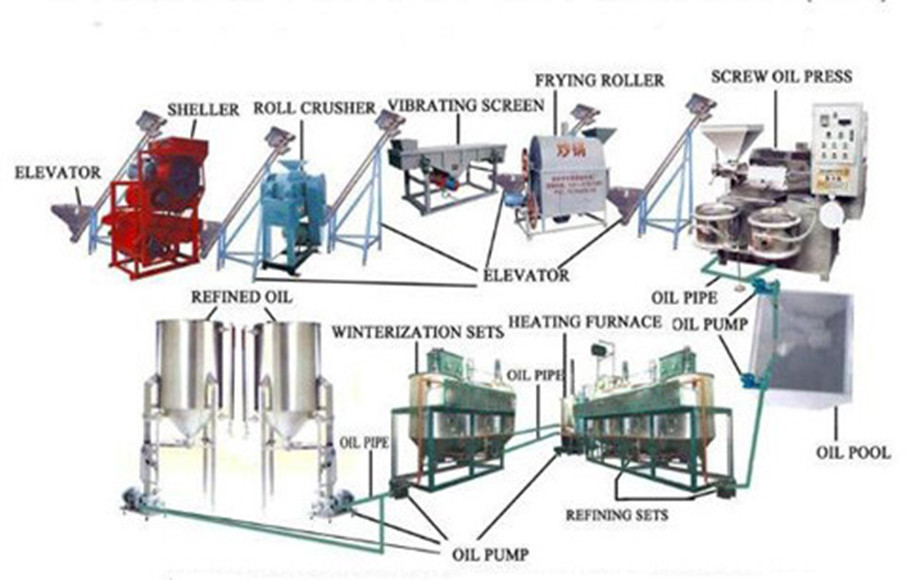

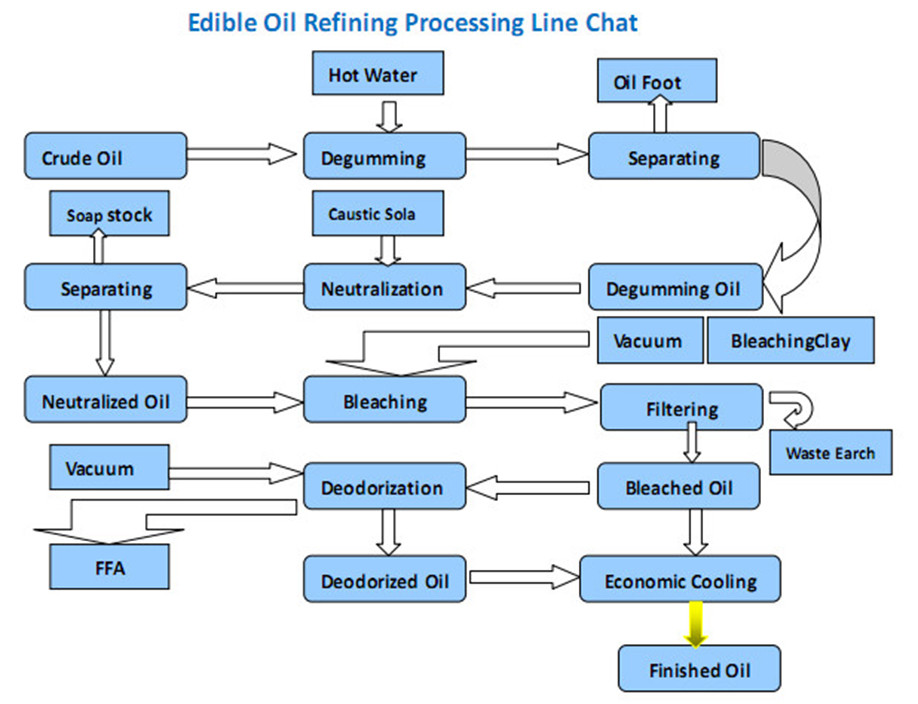

Flow Chat:

Why DIR used oil Waste Engine Oil Distillation Column Oil Refinery Equipment distillation plant is needed?

Used oil should not be thrown away, while it gets dirty. Used oil contains contaminants, but it can be recycled with some technology. In this way, we can not only protect our environment, but also we save some natural resource. So there are many people around the world recycling used oil, taking measures to do that is meaningful.

Waste oil contains too much contamination, including non-hydrocarbon, alkene, polycyclic aromatic hydrocarbon, metal hydronium, impurities, metal particles, asphaltene and colloid etc. The traditional technology only can refine the wasted oil to base oil, which can’t be used directly. Fortunately, our company made great efforts to find new technology in Waste Engine Oil Distillation Column Oil Refinery Equipment distillation plant, which can distill all kinds of waste oil into available oil with high recovery rate. This plant is easier to operate at lower cost.

The purpose of waste oil Waste Engine Oil Distillation Column Oil Refinery Equipment distillation plant is to re-refine industrial waste oil(including equipment lubricants, metal-working oil and process oil) and used automotive lubricants( such as engine oil, hydraulic oil and gear oil), then reuse it.

Distillation is the physical separation of components of lubricating oil by boiling range. Depending on the type of distillation, the boiling ranges can produce gases and gasolines at the lower boiling points with heavy lubricating oils being distilled at higher boiling points. Distillation is the core process for a facility capable of producing re-refined base-oils to virgin base-oil quality.

Certifications

CERTIFICATE:

- ISO CERTIFICATE

- SGS CERTIFICATE

- CE CERTIFICATE

-

1. 1-2 years quality guarantee;

2. Technical consult and mutual discussion

3. Engineers available to go abroad for installing and commissioning machinery

4. Free training for machines installation and operation of the staffs

5. Full set of Manual booklet in English Version

6. If there is something wrong with the equipment, seller should give a response and provide the solution within 24 hours.

7. If there is technological innovation, seller should guide the customer to upgrade.

Wooden Cases:To be packed in strong wooden cases, suitable for long distance Waste Engine Oil Distillation Column Oil Refinery Equipment freight transportation as well as changing climate and with good resistance to moisture and shocks.

TONGRUI’S Advantage:

v TONGRUI’s oil purifier machine always clean used oil at all time, increase your oil life, reduce purchase new oil, achieve resource second use, reduce pollution and protect environment

v TONGRUI has own R&D team, provide different settle blueprint according to customers' special requirement to confirm safety production and decrease cost, high quality products,have good quality control such as CE, ISO9001,2008 and SGS certificates; more than 85% yield rate, low production cost.

v TONGRUI has own factory and skilled worker,rich-experienced design tram and responsible QC and good after-sales service.

v TONGRUI has strict quality control from raw material to finished products,and ensure high quality of your required products, also we manage to control the cost and save every penny for your party.

Contact Me

Any questions, don't hesitate to let us know it. Looking forward to build long friendly relationship with you!

Jinan Joysun Machinery Co., Ltd. basé sur une forte résistance technique, l'amélioration des méthodes de détection, excellent système d'assurance qualité pour assurer que « la qualité d'abord, le premier client », responsable de l'installation et la mise en service, les services techniques et des produits de formation technique, après l'installation est terminée je vais Jinan Joysun Machinery Co., Ltd. techniciens vos opérations de production de l'entreprise du personnel de l'équipement de formation professionnelle et technique et des démonstrations en direct.

Jinan Joysun Machinery Co., Ltd. reposant sur un solide soutien technique, des équipements de production de pointe, la technologie de traitement sophistiqué et des méthodes d'essai scientifiques pour assurer la qualité et la livraison des produits et fournit une des solutions techniques parfaitement optimisées en fonction de vos besoins. Notre champ d'activité international comprend des clients partout dans le monde. Nous avons un prix compétitif, un excellent service après-vente fier. Jinan Joysun Machinery Co., Ltd. attitude de travail de l'amélioration continue et de l'amélioration constante et des idées novatrices mènera Jinan Joysun Machinery Co., Ltd. et vous joignent les mains pour créer brillant avenir ensemble!

Contact Us

- Leader Machinery

- Phone(Working Time)

Product Categories

- Flavor coating machine

- cold pressing oil machine

- biodiesel processing machine

- Bird food machine

- Corn flakes machine

- Dog food machine

- Oil Production Line

- animal oil processing equipment

- pet food extruder machine

- Bread crumbs making extruder processing line

- Puff rice snacks machine

- Core-filled snacks machine

- Oil refining equipment

- oil press machine

- fried chips machine

- Breakfast cereals extrusion line

- Cottonseed oil equipment

- japanese rice cake machine

- Soya meat extrusion line

New Products

High Efficiency soybean crude oil refinery equipment

High Efficiency soybean crude oil refinery equipment 50t/d Crude oil refinery, oil extraction equipment for sunflower/peanut/cottonseed/flax oil

50t/d Crude oil refinery, oil extraction equipment for sunflower/peanut/cottonseed/flax oil modular refinery / crude oil refinery equipment / coconut oil refinery

modular refinery / crude oil refinery equipment / coconut oil refinery Mature technology waste essential oil processing refine unit

Mature technology waste essential oil processing refine unit energy saving soybean oil leaching equipment in 2016

energy saving soybean oil leaching equipment in 2016