Home>Products>Oil refining equipment>Large Capacity Soybean Oil extraction Equipment

Large Capacity Soybean Oil extraction Equipment

- LD

Oil refining equipment

- China

- CE&ISO9001

- One set Large Capacity Soybean Oil extraction Equipment

- Negotiation

- 13m*12M*17M

- Within 5 working days

- paypal,UnionPay, Visa/MasterCard, Amex, Discover,T/T

- 139

-

Leader Machinery2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Leader Machinery2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Product Description

Large capacity Soybean Oil extraction Equipment

Product Description

1 Design Basis

The Capacity is 50TPD Soybean Oil extraction machine

2 Basis of Raw Materials

- Ø Raw materials Quality of Crude Soybean Oil

Item |

Quality index |

||

Smell & taste |

|

Soybean oil inherent original odor and taste |

|

Moisture&Volatiles |

% |

0.2 |

|

Insoluble |

% |

0.2 |

|

Acid Value(KOH) |

(mg/g) |

4.0 |

|

Per Oxide Value |

(mmol/kg) |

7.5 |

|

Residue solvent |

(mg/kg) |

100 |

|

Remark: Higher FFA,insoluble,etc. can lead to decrease in plant capacity and or deteriorated quality of refined oil

- Ø Refined Soybean Oil Quality

Item |

Quality Index |

|||

First grade | ||||

Color |

( dispoable cuvettes 25.4mm) |

----------------- |

||

( dispoable cuvettes 133.4mm) |

Yellow 20 Red 2.0 |

|||

Smell & taste |

|

Odorless &bland |

||

transparency |

|

Clear& Colorless |

||

Moisture&Volatiles |

% |

0.05 |

||

Insoluble |

% |

0.05 |

||

Acid Value(KOH) |

(mg/g) |

0.2 |

||

Per Oxide Value |

(mmol/kg) |

5.0 |

||

Residue solvent |

(mg/kg) |

|

Not be detected |

|

3 Chemicals used

- Ø Phosphoric acid & citric acid

- Ø Bleaching Earth

- Ø Caustic Soda

4 Consumption

- Ø Steam consumption: ≤350kg/T .oil

- Ø Electric Power consumption: ≤50 K.W.H/T .oil

- Ø Water consumption: 200Kg/T. Oil(soften water)

- Ø Phosphoric acid consumption: 1~3 Kg /T .oil

- Ø Citric acid : 1~2 Kg /T.oil

- Ø Caustic soda: acid valve(%)×1 Kg/ T. Oil

- Ø Bleaching Earth consumption: 10~30 Kg /T . Oil

- Ø Residue Oil content in Waste clay: 24%

- Ø Water circulation: about 200M3/h

5 Oil Loss

² In Degumming Section: Oil Loss% == (phosphatide content) %×1.5+(fatty acid content)%×1.8

² In deodorization Section:Oil Loss % == (fatty acid)%×1.2

² In Bleaching section: Oil Loss % == (solid impurity) %×1.4+(Moisture and volatile matter content)%

6 Process Description

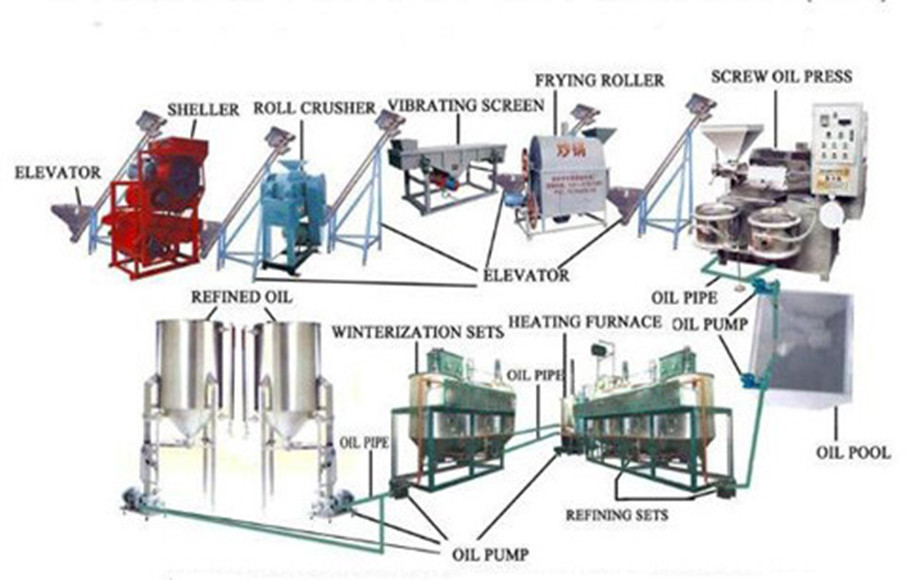

The whole soya bean oil press machine contains three workshops: soy pretreatment workshop soy oil extraction workshop and soy oil refining workshop.

1. Craft flow for soy oil pretreatment workshop

Cleaning :There are some ways to get rid of the impurities, so according to the materials' quality to choose the cleaning way, the common cleaning ways have vibrating screen, sieve etc

Softening: this part is mainly to adjust the temperature and mositure, the equipment is softening pot

Puffing: there are some materials that apply to puffing, such as rice bran, soy etc. through the puffing, we can get higher oil yield, so that you can get more profits.

2.Craft flow for soy oil extraction workshop

Extractor: our company is specilized in making oil machines, as for the extractor, we have there different design: rotocel extractor, loop extractor, chain extractor. we can design for you according to your specification.

Evaproation and steam-stripping: our company adopt negative pressure evaporation ,which can ensure excellent oil quality

DTDC Desolventizer-toaster: we adopt the Large Capacity Soybean Oil extraction Equipment technology to make full use of the meal to produce the animals' meal. full energy-saving design utilizes heat energy for many times and saves steam consumption.

3. Craft flow for soy oil refining workshop

1,continuous alkali refining shortens contact time between oil and lye, which reduces oil saponification state, lowers refining consumption, and improves efficiency.

2, Decolorization craft adopts technology of combing premixing and steam bleaching, which improves bleaching efficiency, saves consumption of bleaching clay, and it is simple and convenient to operate; besides, negative pressure state avoids oxygen in the air from contacting with hot oil, thereby ensuring oil product quality, inhibiting acid value to rise again, and lowering peroxide value.

3, Physical refining section adopts new type continuous deacidification and deodorization craft, which is applicable for vegetable oil of high acid value and low resin content, the actual production proves its most obvious advantages as following: strong deacidification ability, excellent hot bleaching effect, high refining rate, good oil quality etc.

4, the process has multiple heat exchange, which makes full utilization of heat energy, effectively reduces steam consumption, and also has the advantage of adjustable production process, flexible operation, high automatic degree, environment sanitation and so on.

Henan Huatai Food & Oil Machinery Engineering Co., Ltd. (short for HHFOME) is a manufacturing enterprise specialized in producing oil machinery in China. HHFOME consists of Henan Huaxian Grain Machine Factory, Huaxian Hangpeng Grain Machinery Co., Ltd. and Beijing Huakang Xiwang Biological Technology Co., Ltd.. Established in 1988, HHFOME covers an area of 63,000 square meters and has 210 senior engineering technicians. Our company has 202 sets of automatic processing equipment. Processing capacity of our enterprise is more than 3000 sets every year.

HHFOME has obtained independent export rights and has passed the evaluation of ISO9001:2000 Quality System Management Certification. We have got 22 national patents, 4 international awards, 2 national awards and 2 provincial awards.

Our products include copra oil pressing equipment, rice bran oil manufacturing equipment, lignite wax extraction equipment, cottonseed preprocessing equipment and other machinery of oil making field, with 5 series and over 80 kinds.

Our Main Products:

Sets of equipment for rice bran oil making, set of equipment for palm oil fractionation, sets of equipment for cottonseed protein dephenolization, biodiesel continuous production equipment, large scale high-class cooking oil equipment, Class A oil refining equipment, JC-plate extraction equipment and oil filters

Our Services

Turnkey Service of Soybean Oil extraction Line

FAQ

1 Who we are ?

we are the Large Capacity Soybean Oil extraction Equipment manufacture in Edbile Oil Extraction in China with more than 60 years experience. Our company has passed ISO9001, SGS, Certificate. So we can offer you best price and best service.

2 Can you provide Turnkey Service Oversea?

We can do many project all over the world. We have much experience. We provide civil engineering , plant building and equipment installations service.

3 Where your factor location ?

We locate in Zhengzhou City,China. You can fly from Shanghai City to Zhengzhou City, about 1.5 hours and fly from Beijing to Zhengzhou city, about 1 hours.

Our city's international Airport is Zhengzhou Large Capacity Soybean Oil extraction Equipment.

4 24 hours consulting Service

If you want to consult the Edbile Oil Production Line. Please call 18203651296

Jinan Joysun Machinery Co., Ltd. est une grande entreprise par actions, axée sur la production d'Large Capacity Soybean Oil extraction Equipment, intégrée à la recherche scientifique, à la production et aux ventes. La société est située dans la zone industrielle de Shandong salut-technologie, couvre une superficie de 50.000 mètres carrés, avec 15.000 mètres carrés deux standard usine industrielle lourde, plus de 160 ensembles toutes sortes de traitement des métaux de grande et moyenne taille, soudage, équipement d'assemblage .Jinan Joysun Machinery Co., Ltd. attache une grande importance aux échanges techniques et à la coopération internationale, a présenté la technologie de pointe sur et artisanat des États-Unis, Allemagne, Australie et autres pays, établit les lignes de production avancées internationales AAAA et base d'essai moderne de première classe.

Jinan Joysun Machinery Co., Ltd. basé sur une forte résistance technique, l'amélioration des méthodes de détection, excellent système d'assurance qualité pour assurer que « la qualité d'abord, le premier client », responsable de l'installation et la mise en service, les services techniques et des produits de formation technique, après l'installation est terminée je vais 9999999 techniciens vos opérations de production de l'entreprise du personnel de l'équipement de formation professionnelle et technique et des démonstrations en direct.

Contact Us

- Leader Machinery

- Phone(Working Time)

Product Categories

- Flavor coating machine

- cold pressing oil machine

- biodiesel processing machine

- Bird food machine

- Corn flakes machine

- Dog food machine

- Oil Production Line

- animal oil processing equipment

- pet food extruder machine

- Bread crumbs making extruder processing line

- Puff rice snacks machine

- Core-filled snacks machine

- Oil refining equipment

- oil press machine

- fried chips machine

- Breakfast cereals extrusion line

- Cottonseed oil equipment

- japanese rice cake machine

- Soya meat extrusion line

New Products

High Efficiency soybean crude oil refinery equipment

High Efficiency soybean crude oil refinery equipment 50t/d Crude oil refinery, oil extraction equipment for sunflower/peanut/cottonseed/flax oil

50t/d Crude oil refinery, oil extraction equipment for sunflower/peanut/cottonseed/flax oil modular refinery / crude oil refinery equipment / coconut oil refinery

modular refinery / crude oil refinery equipment / coconut oil refinery Mature technology waste essential oil processing refine unit

Mature technology waste essential oil processing refine unit energy saving soybean oil leaching equipment in 2016

energy saving soybean oil leaching equipment in 2016