Home>Products>Oil refining equipment>Crude corn oil refining machinery / sunflower oil refining equipment

Crude corn oil refining machinery / sunflower oil refining equipment

- LD

Oil refining equipment

- China

- ISO CE SGS

- One set Crude corn oil refining machinery / sunflower oil refining equipment

- Negotiation

- 1700*1100*1600mm

- Within 5 working days

- paypal,UnionPay, Visa/MasterCard, Amex, Discover,T/T

- 37

-

Leader Machinery2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Leader Machinery2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Product Description

Crude corn oil refining machinery / sunflower oil refining equipment

Product Description

Crude corn oil refining machinery / sunflower oil refining equipment description:

Corn germ oil refinery plant introduction:

Corn germ is a general kind of material for making edible oil. The whole corn oil refinery plant contains three workshops: corn germ pretreatment workshop, corn germ oil extraction workshop and corn germ oil refinery workshop line.

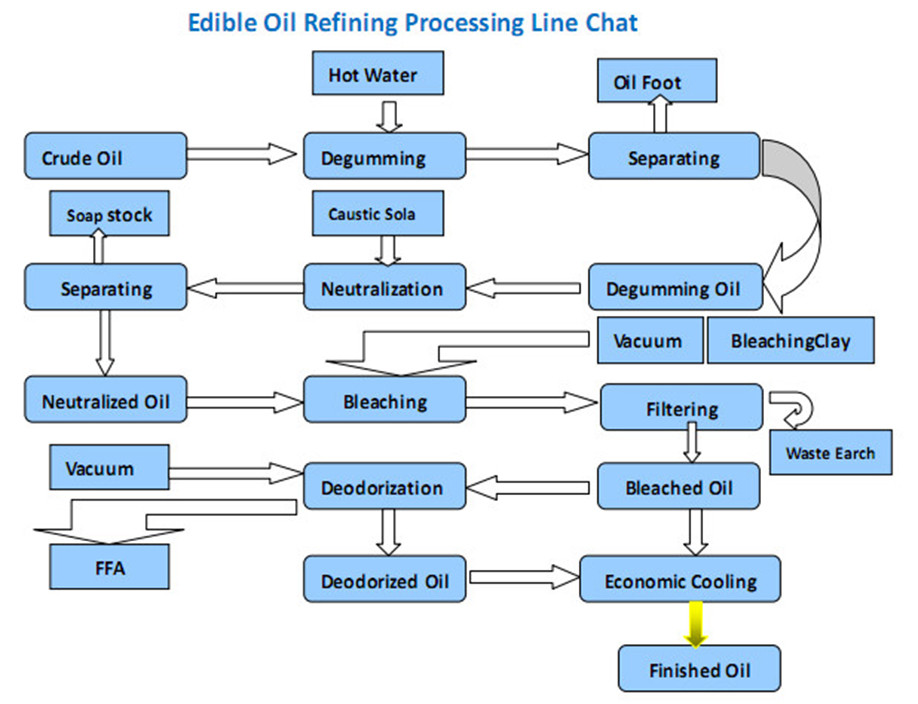

Craft flow for corn germ oil refinery plant:

Crude corn germ oil → degumming and deacidification→ decolorization →deodorization →dewaxing→ refined corn germ oil.

Crude corn oil refining machinery / sunflower oil refining equipment main steps:

1. Crude corn germ oil degumming: In this step gums in crude corn germ oil are removed by hydration with the help of phosphoric acid.

2. Deacidification ( neutralization): In this step free fatty acids are neutralized by using sodium hydroxide and convert them into soap. Additional impurities are also removed by adsorption on soap.

3. Decolorization : During decolorization, unwanted pigments are adsorbed physically and oil will become much clearer.

4. Deodorization: Deodorization is used to remove unacceptable odors by steam distillation, the odoriferous compound are stripped off with the help of live injected steam into heated oil under high Crude corn oil refining machinery / sunflower oil refining equipment pressure.

5. Dewaxing (necessary for cold areas)

Some kinds of oil like sunflower, maize germ or corn oil have to waxes inside, if these impurities are not removed, the oil will freeze easily under low temperature, thus effecting oil quality and appearance. so this process is necessary in extremely cold areas.

1. Ensure to timely provide complete sets of equipment and accessories.

2. Ensure that one-time installation debugging acceptance.

3. Free training technological operator to ensure the trained staff can independent operation.

4. In the installation process, we will offer an experienced project manager, organize a good installation team for the work of field installation debugging.

5. After the equipment field assembly and installation, we will be also responsible for the single equipment debugging, on-line debugging and Feeding trial operation ,to ensure that equipment can normal operate in full load conditions.

6. Warranty period, all because of the quality of products has caused the damage or failure of equipment, suppliers responsible for the free repair and replacing spare part.

Henan hanson machinery co., ltd. Is a domestic and foreign oil equipment engineering contractor, is a collection r & d, design, manufacturing, general contracting of an integrated entity enterprises, business covers grain and oil machinery, chemical equipment, feed machinery, environmental machinery , pressure vessels, mechanical and electrical equipment design, manufacture, installation, commissioning, personnel training and other fields.

Business covers:

Vegetable Oil Series:

♥ Oil pretreatment Equipment, Specifications: 1-1000T/D

♥ Plant Oil leaching equipment, Specifications: 10-1000T/D

♥ Continuous, Semi-continuous physical refining oil complete equipment, Specifications: 5-600T/D

♥ Small Advanced Cooking Oil batch refining unit, Specifications: 1-20T/D.

Workshop showcase

1. Q: Which kind of materials can be processed?

A: All kinds of oil seeds. Such as rice bran,palm,corn germ, cottonseeds, peanut, sunflower, soybean, rapeseed, etc.

2. Q: What's the production capacity can you process?

A: 3-5000 tons per day. We can manufacture as customized order.

3. Q: How long is the warranty?

A: After installing qualified, we guarantee the main parts nature time 1 year.

4. Q: Can you install the machine in local place?

A: Yes, We are a collection of research and development,design, manufacture,installation and training,we have own experienced engines and workers team to go abroad guide the installation,debugging,training.

5. Q: What technical support and doc you can provide after confirm order?

A: 1. Craft flow chart

2. Equipment layout drawings

3. Equipment base drawings

4. Embedded pipeline of power circuit drawings

5. Electricity distribution cabinet and operation table scheme

6. Plant layout drawing

Jinan Joysun Machinery Co., Ltd. est une grande entreprise par actions, axée sur la production d'Crude corn oil refining machinery / sunflower oil refining equipment, intégrée à la recherche scientifique, à la production et aux ventes. La société est située dans la zone industrielle de Shandong salut-technologie, couvre une superficie de 50.000 mètres carrés, avec 15.000 mètres carrés deux standard usine industrielle lourde, plus de 160 ensembles toutes sortes de traitement des métaux de grande et moyenne taille, soudage, équipement d'assemblage .Jinan Joysun Machinery Co., Ltd. attache une grande importance aux échanges techniques et à la coopération internationale, a présenté la technologie de pointe sur et artisanat des États-Unis, Allemagne, Australie et autres pays, établit les lignes de production avancées internationales AAAA et base d'essai moderne de première classe.

Jinan Joysun Machinery Co., Ltd. basé sur une forte résistance technique, l'amélioration des méthodes de détection, excellent système d'assurance qualité pour assurer que « la qualité d'abord, le premier client », responsable de l'installation et la mise en service, les services techniques et des produits de formation technique, après l'installation est terminée je vais 9999999 techniciens vos opérations de production de l'entreprise du personnel de l'équipement de formation professionnelle et technique et des démonstrations en direct.

Contact Us

- Leader Machinery

- Phone(Working Time)

Product Categories

- Flavor coating machine

- cold pressing oil machine

- biodiesel processing machine

- Bird food machine

- Corn flakes machine

- Dog food machine

- Oil Production Line

- animal oil processing equipment

- pet food extruder machine

- Bread crumbs making extruder processing line

- Puff rice snacks machine

- Core-filled snacks machine

- Oil refining equipment

- oil press machine

- fried chips machine

- Breakfast cereals extrusion line

- Cottonseed oil equipment

- japanese rice cake machine

- Soya meat extrusion line

New Products

High Efficiency soybean crude oil refinery equipment

High Efficiency soybean crude oil refinery equipment 50t/d Crude oil refinery, oil extraction equipment for sunflower/peanut/cottonseed/flax oil

50t/d Crude oil refinery, oil extraction equipment for sunflower/peanut/cottonseed/flax oil modular refinery / crude oil refinery equipment / coconut oil refinery

modular refinery / crude oil refinery equipment / coconut oil refinery Mature technology waste essential oil processing refine unit

Mature technology waste essential oil processing refine unit energy saving soybean oil leaching equipment in 2016

energy saving soybean oil leaching equipment in 2016