Home>Products>Puff rice snacks machine>puff snack production extruder machine puff snacks line

puff snack production extruder machine puff snacks line

- LD

Puff rice snacks machine

- China

- ISO9001

- One set puff snack production extruder machine puff snacks line

- Negotiation

- 20.0*4.0*4.0

- Within 5 working days

- paypal,UnionPay, Visa/MasterCard, Amex, Discover,T/T

- 89

-

Leader Machinery2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Leader Machinery2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Product Description

Contact us

Contact Manager.

If you want to know more details about our machine

pls contact me at any time.

Miss Suki

Whatsapp:008618753110771

Skype:sukiexport

Product Description

Product Description

maize puffed food machine cornpuffs extruder

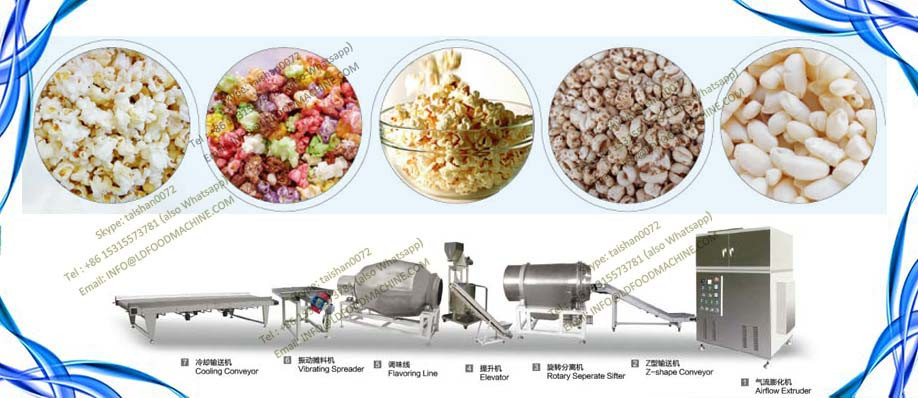

Snacks extruder adopts corn, rice, wheat, oat, barley etc as ingredients to make puffs snack.

Through friction of screw and barrel, the grains are cooked in the extruder Barrel. Forming is at the die face cutter.

The product shape is determined by a combination of the die aperture, including ball, tube, stick, ring, fruit loop, star, wheel and flower etc.

1. Raw materials of maize puffed food machine :

Adopts corn, rice, wheat, oat, barley, millet, sorghum etc as main ingredients.Other material: salt sugar powder, flavor material, cocoa powder and so on….

2. Snacks food Products shapes of maize puffed food machine :

Variety shapes are available for ball, tube, stick, ring, fruit loop, star, wheel and flower and heart shape by adjusting the mould in the extruder

3. maize puffed food machine Capacity:

| Model | Installed power | Real power | Output |

| SLG65 | 70kw | 40kw | 100-150kg/h |

| SLG70 | 90kw | 50kw | 200-240kg/h |

| SLG75 | 100kw | 60kw | 300-360kg/h |

| SLG85 | 120kw | 100kw | 400-500kg/h |

| SLG90 | 135kw | 100kw | 800-1000kg/h |

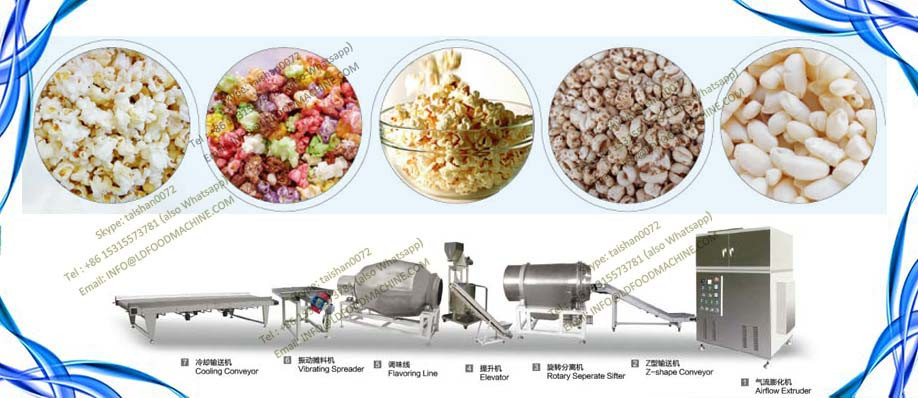

4. Manufacturer corn snack making machine puff snack production extruder machine puff snacks line machine flow chart:

Grain grinder---Mixing system---Twin screw Extrusion system----Drying system----Flavoring system--Packing system

Extruder

ExtruderModel:SLG65;70;75;85;90

Screw diameter: 65mm;70mm;75mm;85mm;90mm.

Screw materials 38CroMnAl

Barrel Steel :45#

Oven

Heating type:Electricity/Gas/Diesel fuel/Microwave

Belt speed:0.1-10m/minutes,

Controlled by inverter.

Temperature: 20-200℃

Material of Construction:SS304

Flavoring

No of drums:1/2

Installed Power:0.75kw

Dimensions/size of roller:3.8*0.8*2.0m

Material of Construction:SS304

5. China standard industrial Voltage for maize puffed food machine :

Three phases: 380V/50Hz, Single phase: 220V/50Hz, We can make it according to customers’ Local voltage according to different countries (400v 415v 480v…….).

6. maize puffed food machine Materials:

All the Snacks food machines are made by stainless steel, this whole line is with reasonable design and with high automation; the screws are made by alloy steel, with building block system structure and self-cleaning function.

Details & Features of maize puffed food machine

1. Alloy (38CrMoAL) screw made by nitriding process, high strength and wear-resting. Self-cleaning ability, no need to discharge or clean the barrel and screw when roasting or replacing of materials.

2. Adopting speed-adjusted converter on feeding system, extrusion system and cutting system. Food grade stainless steel twin screw feeding machine, stable materials feeding in the whole food process.

3. Gearbox with automatic lubrication function, extending gear life.

4. Increased radiator on driving part for forced cooling effect, ensuring extruder operates safely.

5. Barrel with water-cooled circulation, raw materials not only for corn/rice, also for wheat flour/starch with high viscosity. Different moisture-extrusion temperature ratio, whole-expanded and half expanded as different type of products.

FAQ

FAQ1. What`s the raw material of the machine?

puff snack production extruder machine puff snacks line: Our machine`s raw material usually suit for all kinds of powder.If your raw material is not power,We will give you the best suggest according to your selected material.

2. What`s the material of your machine?

puff snack production extruder machine puff snacks line: We use all stainless steel for the parts directly with products.

3.Do you supply any formula to buyers?

puff snack production extruder machine puff snacks line: Yes, we supply formula to buyers.

4.What kind of fuels we can choose during our production?

puff snack production extruder machine puff snacks line: You can choose gas,diesel,electricity as fuels,but pls tell me your idea to me when you ask for quotation.

5.How much area does your machine need for the whole line?

puff snack production extruder machine puff snacks line: The best way is you tell me your workshop area,then I will draw a draft for you to Ensure the rational use of your space.

6.If your country`s power supply is not 3ph 380v 50HZ,different as you in China, could you afford the suitable machine to us?

puff snack production extruder machine puff snacks line: Yes,we can offer the suitable machine according your power,for eg:3ph 380v 60hz;3ph 415v 60hz; 3ph 220v,60hz,and so on.

7.Do you supply packing machine?

puff snack production extruder machine puff snacks line: We have Long-term packing machine supplier, I will be happly to help you to to contact with them.

8.How can I get more discount?

puff snack production extruder machine puff snacks line: Please free to contact with Miss Suki Whatsapp/Cell:008618753110771.

1.Wooden packing for Manufacturer corn snack making machine puff snack production extruder machine puff snacks line machine .

2.All machines apply Fumigation of wooden packaging.

3.We guarantee the quality of packaging to ensure your machines safety.

Our Service

Our ServiceService&Guarantee

a.) Free consultation service before, during, and after sales;

b.) Free project planning and design services;

c.) Free debugging of equipment until everything is functional;

d.) Free management of equipments' long distance shipping from seller's factory to named place by buyer;

e.) Free training of equipment maintenance and operating personally;

f.) Free new production techniques and formulas;

g.) Provide 1 year complete warrantee and life-time maintenance service;The seller is responsible for the nature damage of the machinery in one year except for man-made damage.All spare parts and wearing parts are attached with the machinery for free; and these parts should be enough for one year use.

Our range of products includes:

1) Complete extruded snacks food plant for making products like corn ball, corn ring, corn curl, fried pellet etc.

2) Complete plant to make breakfast cereals in different size and shape and corn flakes.

3) Complete plant to make pet food, dog food, cat food, fish food, bird food etc.

4) Complete plant to make soya portioned food.

5) Complete plant to make fresh Potato, Banana, Cassava, Fruits and Vegetable chips

6) Complete plant to make biscuits and cookies and other bakery items.

7) Complete plant to make roasted and coated nuts, beans and lentils.

8) Complete plant to make Indian Snacks like Namakeen, Sev, Ganthia, Khakhara, Roti, Pappadam etc.

9) Primary and secondary Packing Machines for snacks food products.

10) Tailor made snacks food machine as per specific need of customer.

We, Jinan puff snack production extruder machine puff snacks line Machinery Co., Ltd are located in the famous industry city-Jinan city, capital of Shandong Province.

We are professional manufacturer of food extruder and mainly deal with the manufacture, research and development of the inflating food machine. According to the clients’ different requirements, we could offer the whole complete processing line for all kinds of expanded snacks, corn flakes, nutrition powder, and pet food and so on. Our technical assistance will help clients produce high quality products all the time.

Products Catalogue.

1. Fish feed machine & Fish feed production line

2. Dog feed machine & Animal food production line

3. puff snack production extruder machine puff snacks line machine & puff corn snack extruder machine

4. Extruded Kurkure / Nik Nak Snacks Food Production Line

5. Core Filling / Inflating Snacks Production Line

6. Nutrition Rice / Artificial Rice Production Line

7. Extruded Soya Meat Food Production Line

8. Crispy Chips / Sala / Bugles Production Line

9. Breakfast Cereals / Corn Flakes Production Line

Related Products

Jinan Joysun Machinery Co., Ltd. par l'exploration et la pratique continue, a mis au point un faible investissement, rendement élevé, de faibles coûts d'exploitation, de haute qualité des produits, des avantages de contrôle de facilité d'utilisation, non seulement des avantages « clairvoyante », mais aussi devant le pied.

Pendant ce temps, puff snack production extruder machine puff snacks line particules adjacentes à la vis tourneront avec la rotation de la vis, entraînant la rotation de chaque particule adjacente à la vis avec la rotation de la vis, entraînant une vitesse différente pour chaque particule à l'intérieur de la chambre. Par conséquent, mouvement relatif entre les particules crée de la chaleur qui est nécessaire pendant la fabrication en aidant les protéines à changer correctement, endommager l'huile froide, diminuer la plasticité, diminuer l'huile, l'élasticité, entraînant une haute productivité pétrolière.

Contact Us

- Leader Machinery

- Phone(Working Time)

Product Categories

- Flavor coating machine

- cold pressing oil machine

- biodiesel processing machine

- Bird food machine

- Corn flakes machine

- Dog food machine

- Oil Production Line

- animal oil processing equipment

- pet food extruder machine

- Bread crumbs making extruder processing line

- Puff rice snacks machine

- Core-filled snacks machine

- Oil refining equipment

- oil press machine

- fried chips machine

- Breakfast cereals extrusion line

- Cottonseed oil equipment

- japanese rice cake machine

- Soya meat extrusion line

equipment for peanut flip

equipment for peanut flip Cheez Doodles extruder

Cheez Doodles extruder bread croutons mini bread process equipment

bread croutons mini bread process equipment Puffing rice corn puffs snacks food making extruder line

Puffing rice corn puffs snacks food making extruder line Puffs ring snack food production extruder equipment

Puffs ring snack food production extruder equipment