Home>Products>Bread crumbs making extruder processing line>eco-friendly charcoal powder briquette producing line with Germany technology

eco-friendly charcoal powder briquette producing line with Germany technology

- LD

Bread crumbs making extruder processing line

- China

- CE certification

- One set eco-friendly charcoal powder briquette producing line with Germany technology

- Negotiation

- 1.32*1.23*1.52m

- Within 5 working days

- paypal,UnionPay, Visa/MasterCard, Amex, Discover,T/T

- 121

-

Leader Machinery2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Leader Machinery2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Product Description

Hot selling 2 rollers coal ball pressing machine with CE

Coal/charcoal briquette machine is mainly used for high-density metal scrap (scrap iron, copper scrap, aluminum scrap, etc.), granular powder metal powder (iron powder, aluminum powder, copper powder, lead powder, etc.) , metallurgical additives, sponge iron, etc., without adding any binder pressed into the case of cylindrical cakes of high-density block (weight 2-8 kg), the cake density of up to 5T/M3 block above (the different raw materials, press out the cake block density and not quantity is not the same), pressed into the cake pieces can be directly cast furnace use.

Suitable for the following raw material

- Color and black metallic mine powder: Iron scale, iron sludge, Precipitator dust, Iron concentrate, Raw material powder, Manganese ore fines, Silicomanganese alloy. etc..

- Coal: Coal powder, coke powder, slime peat, middle coal,lignite etc.

- Other material:Charcoal powder, fireproof material, Desulfurized gypsum,Dolomite etc

Final products:

All the above materials can be transformed into different shapes according to buyer's request using different rollers. We list some types bellowed:

Features

Coal/Charcoal briquette machine

1. High quality and efficiency

2. Long Service life

3. Low-consumption,energy saving

Coal/Charcoal briquette mchine Working Principle

This series of briquette machine will pass the power on to the two pressure roller through the reducer.The two sides and roll rotation, in both the rotating roll,Natural materials to enter the ball roll mode, with the roll rotation, material pressure on a small become larger, When the material to the two rollers rotating line contact point, the pressure of materials has reached the peak. Tremendous pressure in the role of line, the materials become a finished product from the powder ball.

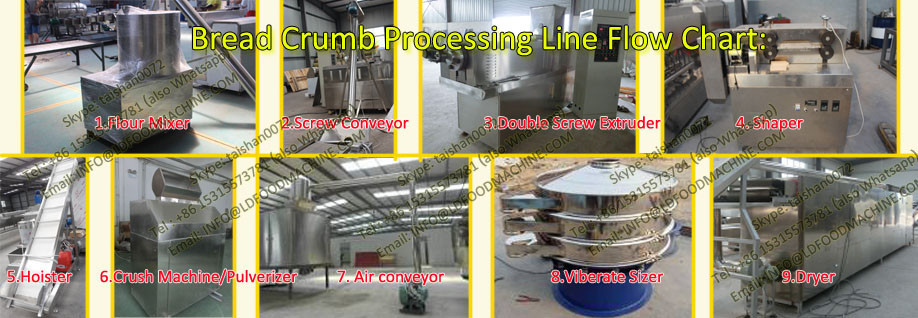

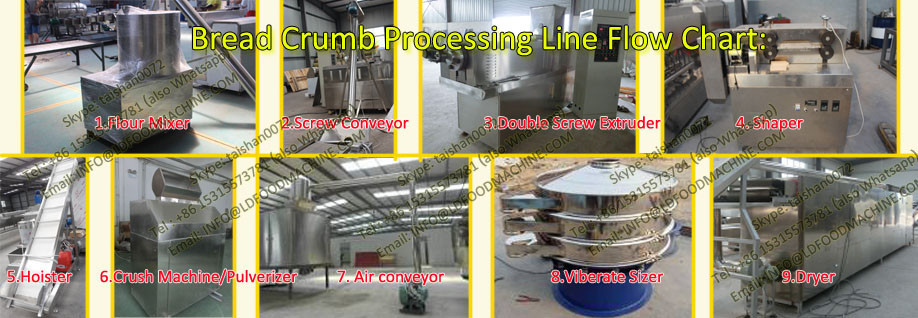

working flowchart

Raw Material—>Crushing—>Feeding—>Mixing—>Pressing—>Drying—>Briquettes

Coal/Charcoal briquette machine Main Technical Parameter:

Model |

Reducer |

speed ratio |

The dimension of pressing roll |

speed of main shaft(r/min) |

Power of motor (kw) |

Output (t/h) |

YHQ360-4 |

ZQ350 |

1:31.5 |

Φ360*250 |

15-17 |

7.5 |

3-5 |

YHQ360-2 |

ZQ350 |

1:31.5 |

Φ360*250 |

15-17 |

7.5 |

3-5 |

YHQ400-4 |

ZQ400 |

1:31.5 |

Φ400*250 |

15-17 |

11 |

4-7 |

YHQ400-2 |

ZQ400 |

1:31.5 |

Φ400*250 |

15-17 |

7.5 |

4-7 |

YHQ430-4 |

ZQ400 |

1:31.5 |

Φ430*250 |

15-17 |

11 |

5-8 |

YHQ430-2 |

ZQ400 |

1:31.5 |

Φ430*250 |

15-17 |

7.5 |

5-8 |

YHQ500-4 |

ZQ500 |

1:31.5 |

Φ500*350 |

15-17 |

22 |

8-10 |

YHQ500-2 |

ZQ500 |

1:31.5 |

Φ500*350 |

15-17 |

15 |

8-10 |

YHQ650-4 |

ZQ650 |

1:31.5 |

Φ650*350 |

15-17 |

30 |

12-20 |

YHQ650-2 |

ZQ650 |

1:31.5 |

Φ650*350 |

15-17 |

22 |

12-20 |

YHQ750-4 |

ZQ750 |

1:31.5 |

Φ750*380 |

14-16 |

30 4

|

25-30 |

YHQ850-4 |

ZQ850 |

1:31.5 |

Φ850*436 |

14-16 |

37 |

35-40 |

YHQ1000-4 |

ZQ1000 |

1:31.5 |

Φ1000*530 |

14-16 |

45 |

40-45 |

About our company:

eco-friendly charcoal powder briquette producing line with Germany technology Xiaoyi Mingyang Machinery Plant

is located in Zhengzhou City, which is the biggest manufacturing base of charcoal making machinery. And we are the one of the earliest and largest manufacturers of renewable fuel & energy equipments and related machinery.

After 15 years development, now our company becomes an independent economic entity with the integration of science, engineering and trading department. our products and are widely accepted in both domestic and world market, and also exported to more than 30 countries, such as England, Russia, Sweden, Poland, Iran, Sudan, South Malaysia, Indonesia, Vietnam, etc.

Our main production line include:

Charcoal / Biomass Briquette Plant for Agro-Forestry Wastes

Wood Pellet Mill / Feedstuff Pelletizing Plant

oil press machine

Animal feed pellet machine

Nail making machinery plant

Roller Briquette Press for Coal / Charcoal powder

Cold rolling mill

Why the client choose us,because :

- one of the largest manufactures of the briquette machine in China

- the earliest manufacture of the briquette machine in China with 20 years experience,

- get the ISO certificate and SGS certificate

- We have the test center of the machine, and we bulit one realted company ( making the briquette and charcoal )with our machine.

- Every machine will test before delivery and we will send the test video and other realted video to our client

- all the motor of the machine with the CE certificate

- product quality get the local government guarantee

- recommend clients for free, offer the layout drawing and the profit table

- change the electrical power for free during warranty time.

- offer the install video and free stuff training

We hope sincerely to become your Chinese supplier and partner in the mechanical field.

If you need help, please contact with us

Jinan Joysun Machinery Co., Ltd. est une grande entreprise par actions, axée sur la production d'eco-friendly charcoal powder briquette producing line with Germany technology, intégrée à la recherche scientifique, à la production et aux ventes. La société est située dans la zone industrielle de Shandong salut-technologie, couvre une superficie de 50.000 mètres carrés, avec 15.000 mètres carrés deux standard usine industrielle lourde, plus de 160 ensembles toutes sortes de traitement des métaux de grande et moyenne taille, soudage, équipement d'assemblage .Jinan Joysun Machinery Co., Ltd. attache une grande importance aux échanges techniques et à la coopération internationale, a présenté la technologie de pointe sur et artisanat des États-Unis, Allemagne, Australie et autres pays, établit les lignes de production avancées internationales AAAA et base d'essai moderne de première classe.

Jinan Joysun Machinery Co., Ltd. basé sur une forte résistance technique, l'amélioration des méthodes de détection, excellent système d'assurance qualité pour assurer que « la qualité d'abord, le premier client », responsable de l'installation et la mise en service, les services techniques et des produits de formation technique, après l'installation est terminée je vais 9999999 techniciens vos opérations de production de l'entreprise du personnel de l'équipement de formation professionnelle et technique et des démonstrations en direct.

Contact Us

- Leader Machinery

- Phone(Working Time)

Product Categories

- Flavor coating machine

- cold pressing oil machine

- biodiesel processing machine

- Bird food machine

- Corn flakes machine

- Dog food machine

- Oil Production Line

- animal oil processing equipment

- pet food extruder machine

- Bread crumbs making extruder processing line

- Puff rice snacks machine

- Core-filled snacks machine

- Oil refining equipment

- oil press machine

- fried chips machine

- Breakfast cereals extrusion line

- Cottonseed oil equipment

- japanese rice cake machine

- Soya meat extrusion line

powerful and useful dry bread crumb production line

powerful and useful dry bread crumb production line bread crumbs making machine production line

bread crumbs making machine production line automatic panko bread crumbs powder making equipment

automatic panko bread crumbs powder making equipment panko bread crumb process line extruder

panko bread crumb process line extruder panko bread crumbs machines maker process line

panko bread crumbs machines maker process line