Home>Products>Oil refining equipment>High quality factory direct manufacturer tire pyrolysis oil refining machine

High quality factory direct manufacturer tire pyrolysis oil refining machine

- LD

Oil refining equipment

- China

- CE ISO SGS

- One set High quality factory direct manufacturer tire pyrolysis oil refining machine

- Negotiation

- Continued

- Within 5 working days

- paypal,UnionPay, Visa/MasterCard, Amex, Discover,T/T

- 175

-

Leader Machinery2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Leader Machinery2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Product Description

| Iteams | Diesel(after distillation) | Mixed Oil, Pyrolysis Oil | GB 0# Diesel |

| Oxidationn Stability | 2.0 | 1.5 | 2.5 |

| Volume % | 0.005 | 0.005 | 0.05 |

| Steam Residual Carbon Residue % | 0.25 | 0.25 | 0.3 |

| Ashes % | 0.008 | 0.1 | 0.01 |

| Copper Corrosion / Level | 1.1 | 1.1 | 1 |

| Water % | Traces | 1 | Traces |

| Mechanical Impurities | No | No | No |

| Density | 0.85 | 0.88 | 0.83-0.87 |

| Freezing Point / °C | -10 | -5 | 0 |

| Flash Point (closed)/ °C | 45 | 40 | 55 |

| Kinematic Viscosity | 2.5 | 5.0 | 3.0-8.0 |

| Combustion Value | 9500 | 10000 | 8500 |

| Color | 1.2 | 4.5 | ≤3.5 |

| Cetane Number | 43 | 38 | 46 |

How to Convert Waste Tyres into Fuel Oil through Pyrolysis Process:

1. Put pre- processed tyres into the reactor by full-automatic feeding machine(taking the fully continuous tyre pyrolysis plant for example) after they are delivered into stock bin by conveyor belt. Total quantity shall be controlled under 2/3 of reactor for rotating more smoothly. Then close the feeding door and open the heating system.

2. From 100 ℃ to 250 ℃ is the preliminary stage , and the oil gas shall be released at 200 ℃ . From 280 ℃ to 350 ℃ is the top output rate interval. Oil gas will be collected into manifold, and the heavy particles and oil will be gathered and liquefied in center of manifold and drop down into the heavy pyrolysis oil tank. The lighter gas will rise up to the multi-functional oil condensers, then be liquefied into oil and stored in the oil tank. The incondensable gas through desulfuration and de-dusting by hydroseal will be led to the furnace for heating.

3. Cool down the reactor after the pyrolysis process. The carbon black will be discharged when the temperature reaches between 50 degrees and 70 degrees. The end products you can get from the waste tyre to oil process are tyre pyrolysis oil, carbon black, steel wire and combustible gas.

Main Features:

1. High Oil Yield. Generally speaking, the oil yield of rate our tyre to oil plant can reach 45%-50% for the big waste tyres. For the small waste tyres, the oil yield rate can be 35%-40%. The oil yield rate may be the most important factor when you choose a waste tyre pyrolysis oil plant. In addition, ou plant uses the rotary condenser, which can promote oil yield and make it convenient to maintain the plant.

2. High quality factory direct manufacturer tire pyrolysis oil refining machine service life. The new heating structure is unique in the market, which combines the advantage of directly heating and hot-wind heating. Thus the new hating system can increases heating speed and prolong the service life of the plant. At the same time , it can aslo improve production efficiency and reduce production cost.

3. Safety guarantee. The whole tyre to oil pyrolysis process needs high temperature. Thanks to the casing outside of reactor, the high temperature will not cause harm to the people around the plant.

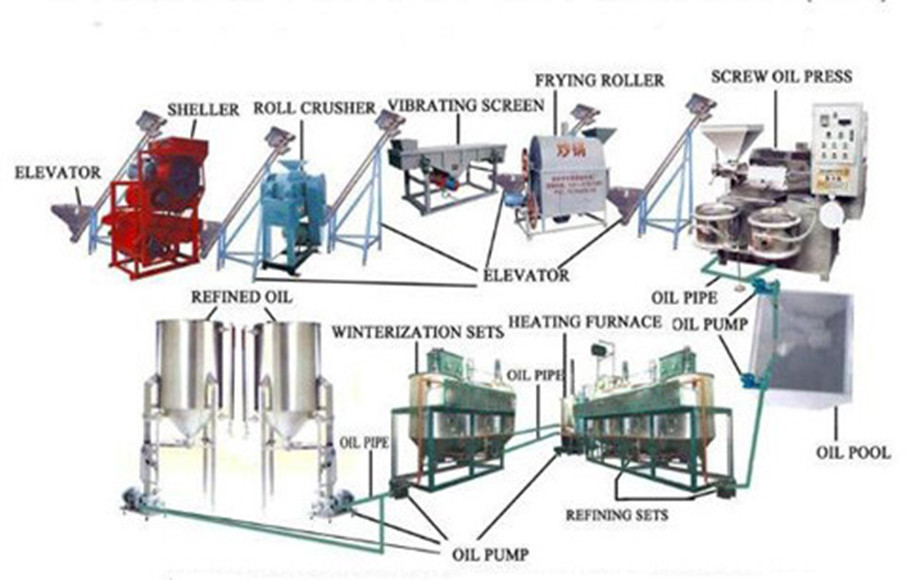

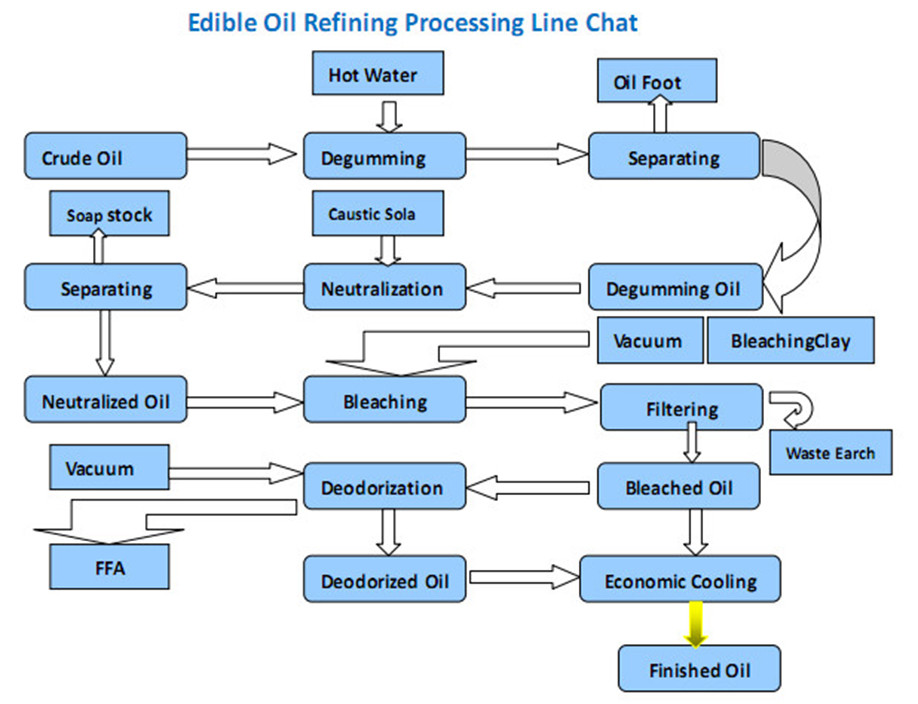

Product Pictures

Our Services

2.Pre-sales:

For customer to understand our product in the round more expediently, we provide online, telephone, email, mobile phone App etc. all-around consult ways for customer to choose, and we provide professional and productive real-time solution aiming at customers’ question. According customers’ different demands, Ruixin engineers provide customized service such as product standard, technological production norm and professional project planning and so on. Saving cost, improving performance for customer and satisfying needs of customers adequately.

3.In-sale Service:

Ruixin New Energy and Technology Development Co., Ltd promises customers that the product will be made in the most advanced technology and use the better materials to meet the requirements of the quality,specifications,performance of the contract and guarantee the product provided in the period of validity has satisfactory performance. We will regulate equipment production progress for our customers and timely and effectively communicate with customers to guarantee delivery within the stipulated time. After the completion of the production equipment, the personnel of quality inspection will control the quality strictly and will do the inspection before the goods will be sent. If the inspection cannot meet the requirement, the goods would not be sent.

4.After-sales:

Within 24 hours after installation and debugging is completed we will pay a return visit by the telephone about the degree of satisfaction of the service to rebuild the comprehensive maintenance and service records file. If the customers found the problems during the use, we would offered the timely, positive feedback and sufficient technical support. Ruixin New Energy and Technology Development Co., Ltd will offer the maintenance that is not on a regular basis. The product warranty lasts for one year .During the warranty ,we will be responsible for the fault caused by the design,technology and materials : If the product would be unavailable caused by the quality, we would be free for the replacement and the installation.

Jinan Joysun Machinery Co., Ltd. par l'exploration et la pratique continue, a mis au point un faible investissement, rendement élevé, de faibles coûts d'exploitation, de haute qualité des produits, des avantages de contrôle de facilité d'utilisation, non seulement des avantages « clairvoyante », mais aussi devant le pied.

Pendant ce temps, High quality factory direct manufacturer tire pyrolysis oil refining machine particules adjacentes à la vis tourneront avec la rotation de la vis, entraînant la rotation de chaque particule adjacente à la vis avec la rotation de la vis, entraînant une vitesse différente pour chaque particule à l'intérieur de la chambre. Par conséquent, mouvement relatif entre les particules crée de la chaleur qui est nécessaire pendant la fabrication en aidant les protéines à changer correctement, endommager l'huile froide, diminuer la plasticité, diminuer l'huile, l'élasticité, entraînant une haute productivité pétrolière.

Contact Us

- Leader Machinery

- Phone(Working Time)

Product Categories

- Flavor coating machine

- cold pressing oil machine

- biodiesel processing machine

- Bird food machine

- Corn flakes machine

- Dog food machine

- Oil Production Line

- animal oil processing equipment

- pet food extruder machine

- Bread crumbs making extruder processing line

- Puff rice snacks machine

- Core-filled snacks machine

- Oil refining equipment

- oil press machine

- fried chips machine

- Breakfast cereals extrusion line

- Cottonseed oil equipment

- japanese rice cake machine

- Soya meat extrusion line

New Products

High Efficiency soybean crude oil refinery equipment

High Efficiency soybean crude oil refinery equipment 50t/d Crude oil refinery, oil extraction equipment for sunflower/peanut/cottonseed/flax oil

50t/d Crude oil refinery, oil extraction equipment for sunflower/peanut/cottonseed/flax oil modular refinery / crude oil refinery equipment / coconut oil refinery

modular refinery / crude oil refinery equipment / coconut oil refinery Mature technology waste essential oil processing refine unit

Mature technology waste essential oil processing refine unit energy saving soybean oil leaching equipment in 2016

energy saving soybean oil leaching equipment in 2016