Home>Products>Oil refining equipment>Kernel Husk Separation Equipment of Pre-treatment Section in Oil Press Plant

Kernel Husk Separation Equipment of Pre-treatment Section in Oil Press Plant

- LD

Oil refining equipment

- China

- CE ISO9001 SGS

- One set Kernel Husk Separation Equipment of Pre-treatment Section in Oil Press Plant

- Negotiation

- Within 5 working days

- paypal,UnionPay, Visa/MasterCard, Amex, Discover,T/T

- 133

-

Leader Machinery2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Leader Machinery2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Product Description

Kernel Husk Separation Equipment of Pre-treatment Section in Oil Press Plant

Company Information20 years manufacturing, sales and installation experience on oil process project.

38 technical engineers research on new efficient processing craft and instruct manufacturing and installation.

78 technicians-professional installation team-with rich and mature installation and training experience.

CE, ISO9001 and SGS Certified

Product Description

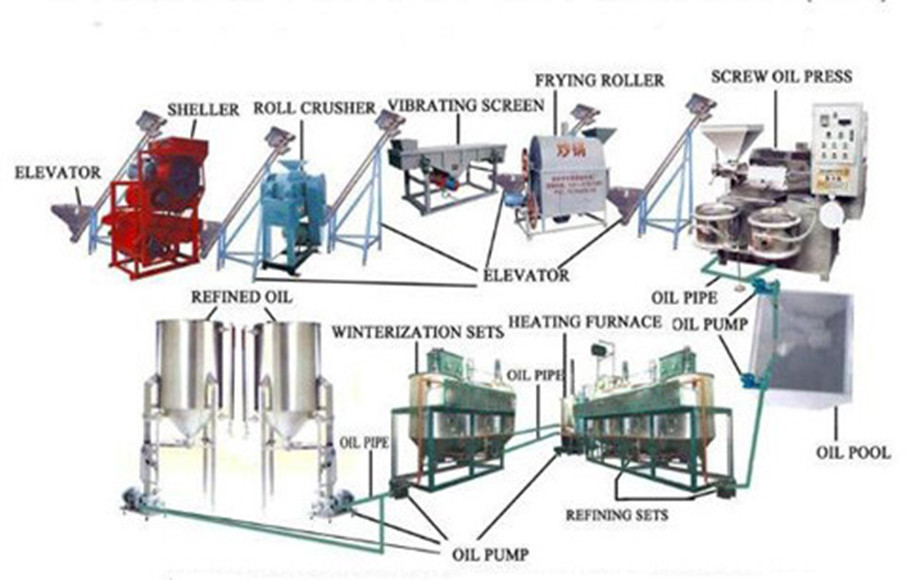

Full set equipments of Oil mill machinery, the working flow chart is as following:

Applicable to oil seed material

This technology is applicable to kinds of oil-bearing material, such as peanut, rapeseed, sunflower seed, castor bean, maize germ, tea seed, oil palm seed, rice bran, sesame, shea nuts, tung nut, copra, hemp seed, flaxseed, olive, walnut, perilla seed, oil melon, tallow seed, castor seed, eveing primrose seed, corn germ, safflower seed, almond, pepper seed, etc.

Our Services

- Raw material and finished Oil products Storage equipments

- Oil seeds pretreatment and press production line: 5-4000T per 24 hrs

- Solvent extraction production line: 10-4000T per 24 hrs

- Edible oil refinery production line: 1-600T per 24 hrs

- Oil fractionation engineering

- Biodiesel production line: 1-600T per 24 hrs

Production Flow

Cleaning equipments of pre-treatment section in press plant

De-stoner of pre-treatment section in press plant

Shelled equipment of pre-treatment section in press plant

Kernel husk separation equipment of pre-treatment section in press plant

Material breaking equipment of pre-treatment section in press plant

Flaking equipment in pre-treatment section in press plant

Softing equipment in press plant

Finished Product

Packaging & Shipping

Proffessional packaing team of oil milling machiery for overseas shipping

FAQ

Any of your questions are wormly welcomed, it is Susan Chou (Skype: Susanzhou2u) here to serve you:

Jinan Joysun Machinery Co., Ltd. est une société spécialisée dans la production d'extrudeuse alimentaire à double vis, d'extrudeuse monovis, d'équipements de torréfaction et de stérilisation à micro-ondes, etc. Bien que basée sur le marché domestique, l'entreprise ouvre et exploite positivement le marché étranger. Jusqu'à présent, nos produits Kernel Husk Separation Equipment of Pre-treatment Section in Oil Press Plant ont été exportés de nombreux comtés et régions, y compris la Russie, l'Europe, l'Afrique, la Corée, l'Indonésie, l'Ouzbékistan et la part de marché augmente progressivement d'année en année. Jinan Joysun Machinery Co., Ltd. continuera à être agressif, créatif et apporter une contribution au développement de l'industrie alimentaire de notre pays avec ses pairs à la maison et à l'étranger.

Contact Us

- Leader Machinery

- Phone(Working Time)

Product Categories

- Flavor coating machine

- cold pressing oil machine

- biodiesel processing machine

- Bird food machine

- Corn flakes machine

- Dog food machine

- Oil Production Line

- animal oil processing equipment

- pet food extruder machine

- Bread crumbs making extruder processing line

- Puff rice snacks machine

- Core-filled snacks machine

- Oil refining equipment

- oil press machine

- fried chips machine

- Breakfast cereals extrusion line

- Cottonseed oil equipment

- japanese rice cake machine

- Soya meat extrusion line

New Products

High Efficiency soybean crude oil refinery equipment

High Efficiency soybean crude oil refinery equipment 50t/d Crude oil refinery, oil extraction equipment for sunflower/peanut/cottonseed/flax oil

50t/d Crude oil refinery, oil extraction equipment for sunflower/peanut/cottonseed/flax oil modular refinery / crude oil refinery equipment / coconut oil refinery

modular refinery / crude oil refinery equipment / coconut oil refinery Mature technology waste essential oil processing refine unit

Mature technology waste essential oil processing refine unit energy saving soybean oil leaching equipment in 2016

energy saving soybean oil leaching equipment in 2016