Home>Products>Oil refining equipment>refiner rice mill and small oil refining equipment vegetable oil refining

refiner rice mill and small oil refining equipment vegetable oil refining

- LD

Oil refining equipment

- China

- ISO

- One set refiner rice mill and small oil refining equipment vegetable oil refining

- Negotiation

- 1700*1100*1600mm

- Within 5 working days

- paypal,UnionPay, Visa/MasterCard, Amex, Discover,T/T

- 108

-

Leader Machinery2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Leader Machinery2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Product Description

Product Description

Company profiles:

QIE grain and oil machinery co., LTD,a leader with 33 years experience ,is a company specializing in the production of grain and oil machinery and equipment, scientific research, manufacturing, sales for the integration of large-scale private enterprises, the company with the mechanical design and research institute of henan province, henan university of technology (the former college of food) university-enterprise cooperation, carried out for a long time in oil machinery, preparing protein, lecithin extraction and other aspects of the research and development and application of new technology.

Product Description

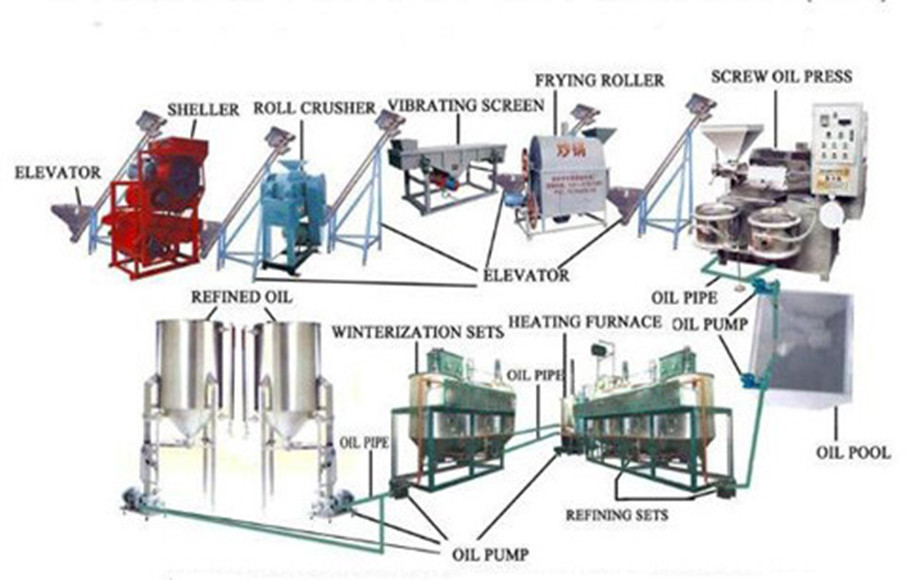

Product Description1. pre-press machine of small oil refining equipment:

It is necessary for hulling the peanut seeds before pressing, so it could reduce the wax content of final oil, whcih is bad for human.

Normally the oil pressing plant is composed of seeds cleaning & crushing unit, steaming and drying units, pressing unit, conveyor, electrical cabinet box, etc. The oil pressing unit as the main stage, to make the vegetable seeds flake in a hardened cage to squeeze oil content out. It's complete set of oil pressing equipment, which is automatically operated to save more labor and cost.

Including to the following machinery and parts:

Electrical apparatus control, materials feeder, conveyer, screening machine, steaming & frying machine, huller machine, medium boilor etc.

The by-products from the oil press are cake and soap residue. The cake could be used as animal food with our pelleting machinery, or source material for the other way of extraction. Soap residue is the source material for laundry soap with soap making machinery and washing detergent.

2.oil extraction of small oil refining equipment

The second way to extract oil for using chemical solvent to dissolve oil content contained in cake or direct oil seeds, only for lower oil seeds, for example soybean.

Then oil is separated from solvent by vaporizing solvent out. In configuring the solvent extraction plant, pre-pressing may be involved in which case seeds are lightly pressed, and which leaves about 14% to 18% oil in the pressed cake.

Solvent extraction will further process these cakes and leave less than 1% oil in the final cake. This method results in higher yields, more oil; Lower power consumption, lower wear & tear / maintenance and high extract efficiency.

Thus it could be used as complement equipment to extract the oil remained in cake, which yields are extra profits. Certainly if the capacity is less than 50 tons, or it is high rate of output oil, this process could be saved.

3.small oil refining equipment process

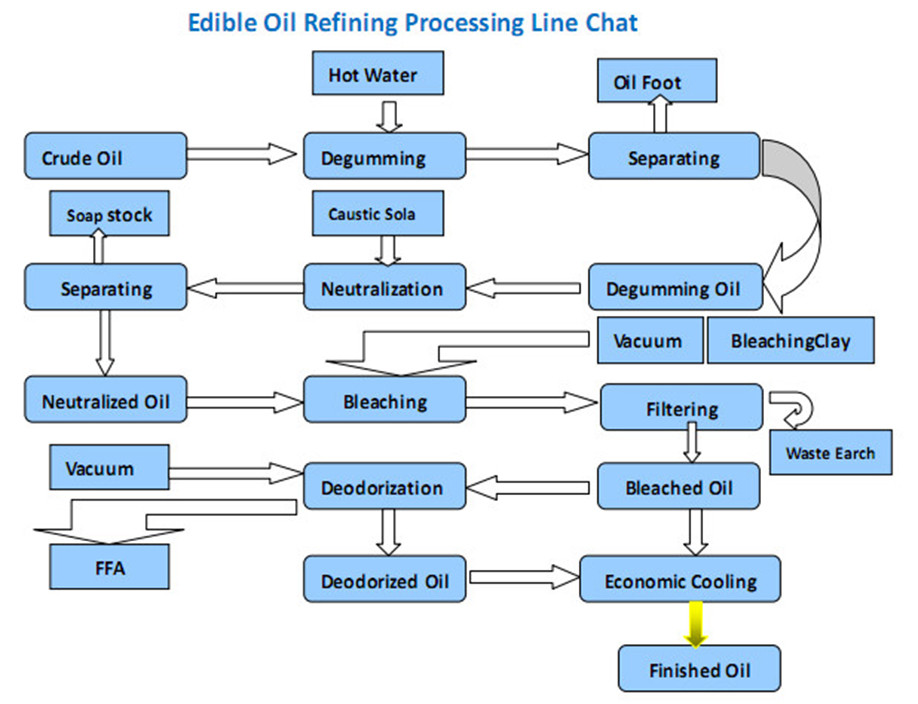

The crude peanut oil from above mentioned two ways of extracting, oil pressing and/or solvent extraction, will be pumped into oil refinery units to produce cooking oil at various grades.

The main equipment of oil refinery is various kinds of vessels and tanks carrying on different tasks with additives.

These tasks may include sedimentation/filtering, neutralization (removing free fatty acid), degumming, decolorization (bleaching), deodorization, especially the dewax process is necessary, more wax would destroy the quality of sunflower oil.

Different combination of steps and the treating degree of each step result in different grade cooking oil and salad oil.

Refinery Processing

Refinery ProcessingCentrifugal machine of small oil refining equipment

Mainly to remove the oil caused by the smell of the material. The process of removing these undesirable odors is called deodorization.

Small oil refining machine:

The activated white earth content 15-20% activated carbon, it should pre-heating before they contact. Make the moisture down, then the activated white earth will not be wet. Last should filter activated white earth by chip-type shake screening.

Deodorization tower of small oil refining equipment

refiner rice mill and small oil refining equipment vegetable oil refining stripping deodorization: The peculiar smell impurity and oil have different volatility. Under the condition of high temperature and high refiner rice mill and small oil refining equipment vegetable oil refining, let the peculiar smell impurity stripping with steam to deodorization.

Semi-continuous physical refinery of small oil refining equipment

Its called bleaching,dewatering pot, its used to remove water from oil by refiner rice mill and small oil refining equipment vegetable oil refining. The bleaching earth is breathed into bleaching pot, after stirring; the bleaching earth is filtrated by filter, so the color of the oil is changed.

Degumming of small oil refining equipment

This is the most important section of hydrate de-gumming, manage the adding water (there is a little P-acid in the water) amount, temperature and add water speed, usually water adding amount is about 3 times of phospholipid content, that is 3-10% oil weight, water temp needs to be higher than oil temp.

Deacidification of small oil refining equipment

This part adopt alkali refining method, that is use alkalis like (NaOH) to neutral the free fatty acid in oil, during this process it will produce soapstock , then separated from the oil by setting several hours. NAOH solution, not only neutral free fatty acid, also can act with other matters like protein, mucus, phospholipid, pigment. After settling, release the soapstock from the tank bottom. Adding hot water to rinse, remove off the leftover lye , soap and some unhydrated phospholipid in the oil. Finally pumping out soapstock from the tank bottom.

Decolorization of small oil refining equipment

In normal situation , there is pigment in the crude oil , we need to using the active clay to absorb the pigment away , after 20 mins , we use the vibrating filter to filter the waste clay away . If you want to get light color oil , you need to add more active clay . That is mean , the customer can accord to his requirement to control the oil color. This process is carried out under the refiner rice mill and small oil refining equipment vegetable oil refining condition.

Certifications

Our Service

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Packing & Delivery

| Packaging | |

| Size | 123 (L) * 456 (W) * 789 (D) |

| Weight | 1.2 T |

| Packaging Details |

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

| Packaging | |

| Size | 123 (L) * 456 (W) * 789 (D) |

| Weight | 1.2 T |

| Packaging Details |

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

AS219 oil refinery machine corn oil refinery mini oil refinery for sale

91.8% Response Rate

Sunflower oil refinery in turkey

91.8% Response Rate

Products Name

91.8% Response Rate

Contact Us

Please send the inquiry to me, waiting for your coming to China and visit our plant

Jinan Joysun Machinery Co., Ltd. est une grande entreprise par actions, axée sur la production d'refiner rice mill and small oil refining equipment vegetable oil refining, intégrée à la recherche scientifique, à la production et aux ventes. La société est située dans la zone industrielle de Shandong salut-technologie, couvre une superficie de 50.000 mètres carrés, avec 15.000 mètres carrés deux standard usine industrielle lourde, plus de 160 ensembles toutes sortes de traitement des métaux de grande et moyenne taille, soudage, équipement d'assemblage .Jinan Joysun Machinery Co., Ltd. attache une grande importance aux échanges techniques et à la coopération internationale, a présenté la technologie de pointe sur et artisanat des États-Unis, Allemagne, Australie et autres pays, établit les lignes de production avancées internationales AAAA et base d'essai moderne de première classe.

Jinan Joysun Machinery Co., Ltd. basé sur une forte résistance technique, l'amélioration des méthodes de détection, excellent système d'assurance qualité pour assurer que « la qualité d'abord, le premier client », responsable de l'installation et la mise en service, les services techniques et des produits de formation technique, après l'installation est terminée je vais 9999999 techniciens vos opérations de production de l'entreprise du personnel de l'équipement de formation professionnelle et technique et des démonstrations en direct.

Contact Us

- Leader Machinery

- Phone(Working Time)

Product Categories

- Flavor coating machine

- cold pressing oil machine

- biodiesel processing machine

- Bird food machine

- Corn flakes machine

- Dog food machine

- Oil Production Line

- animal oil processing equipment

- pet food extruder machine

- Bread crumbs making extruder processing line

- Puff rice snacks machine

- Core-filled snacks machine

- Oil refining equipment

- oil press machine

- fried chips machine

- Breakfast cereals extrusion line

- Cottonseed oil equipment

- japanese rice cake machine

- Soya meat extrusion line

New Products

High Efficiency soybean crude oil refinery equipment

High Efficiency soybean crude oil refinery equipment 50t/d Crude oil refinery, oil extraction equipment for sunflower/peanut/cottonseed/flax oil

50t/d Crude oil refinery, oil extraction equipment for sunflower/peanut/cottonseed/flax oil modular refinery / crude oil refinery equipment / coconut oil refinery

modular refinery / crude oil refinery equipment / coconut oil refinery Mature technology waste essential oil processing refine unit

Mature technology waste essential oil processing refine unit energy saving soybean oil leaching equipment in 2016

energy saving soybean oil leaching equipment in 2016