Home>Products>Oil refining equipment>SINODER hot sale soybean oil refinery plant ,refined sunflower cooking oil equipment

SINODER hot sale soybean oil refinery plant ,refined sunflower cooking oil equipment

- LD

Oil refining equipment

- China

- CE

- One set SINODER hot sale soybean oil refinery plant ,refined sunflower cooking oil equipment

- Negotiation

- refer to model

- Within 5 working days

- paypal,UnionPay, Visa/MasterCard, Amex, Discover,T/T

- 31

-

Leader Machinery2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Leader Machinery2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Product Description

SINODER hot sale soybean oil refinery plant ,refined sunflower cooking oil equipment hot sale soybean oil refinery plant ,refined sunflower cooking oil equipment

Product DescriptionBrief intorduction

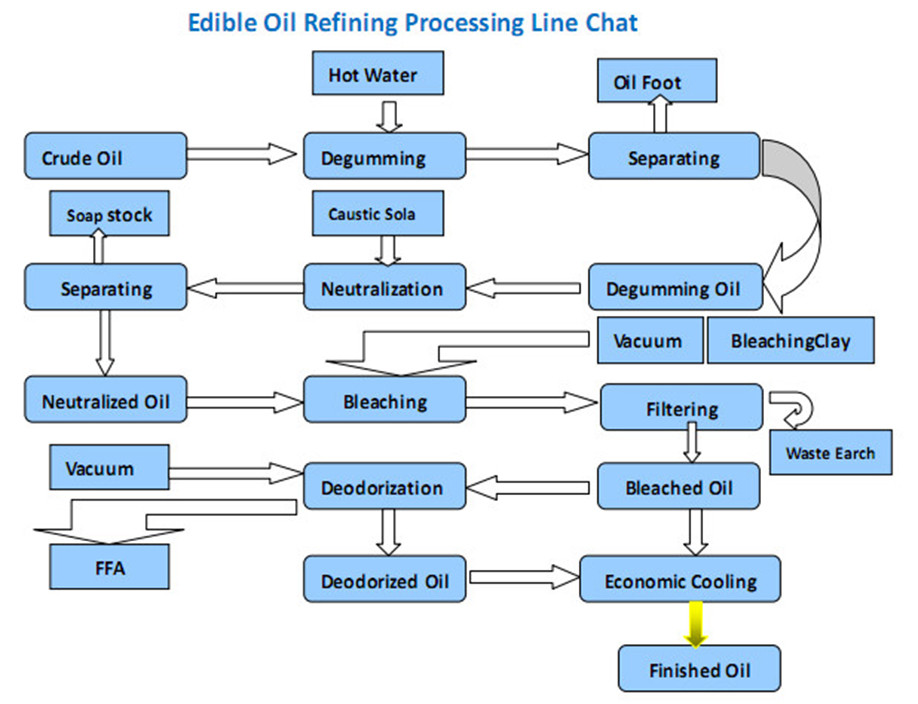

1)Oil refinery plant refers to a series of refining processes that can remove phospholipids, FFA, pigment, off-flavor and other impurities in the oil. Edible oil refinery or vegetable oil refinery is essential to ensure removal of gums, waxes, phosphatides and free fatty acid (F. F.A.) from the oil. To impart uniform colur by removal of coloring pigments and to get rid of unpleasant smell from the oil by removal of odiferous matter.

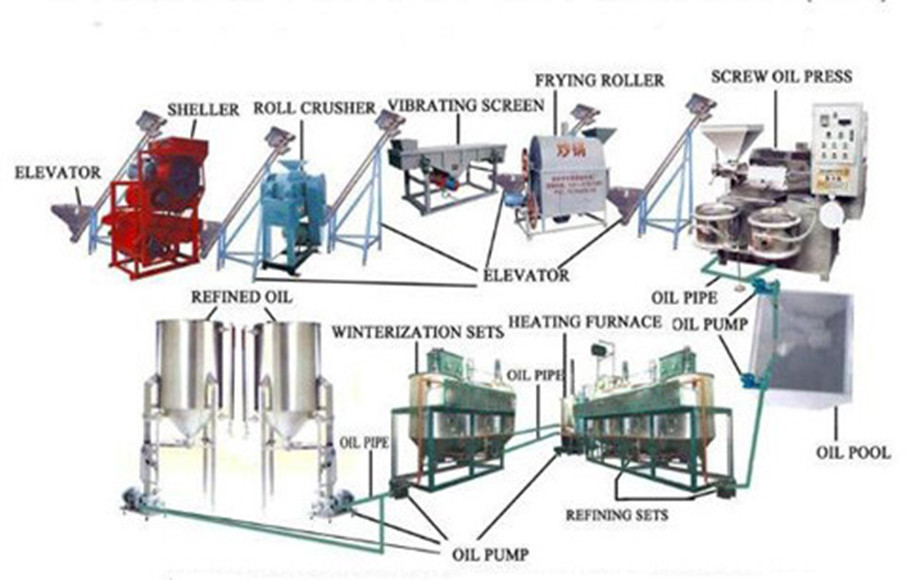

2)Oil refining is according to the different usage and requirements, utilizing the physical methods and chemical processes to get rid of the harmful impurities and needless substance in the crude oil, getting standard oil.. il refinery plant usually includes the following sections: Degumming, Neutralization, Bleaching, Dewaxing and Deodorization The process of removing these impurities after oil extraction section is called oil refining Oil Refinery machinery, oil extract

Main process

1.Degumming with water to remove the easily hydratable phospholipids and metals.

2.Addition of a small amount of phosphoric or citric acid to convert the remaining non-hydralable phospholipids (Ca, Mg salts) into hydratable phospholipids.

3.Neutralising of the free fatty acids with a slight excess of sodium hydroxide solution, followed by the washing

4.Bleaching with natural or acid-activated clay minerals to adsorb colouring components and to decompose hydroperoxides.

5.Deodorising to remove volatile components, mainly aldehydes and ketones, with low threshold values for detection by taste or smell. Deodorisation is essentially a steam distillation process carried out at low pressures

(2-6 mbar) and elevated temperatures (180-220°C).

Company Information

Zhengzhou SINODER hot sale soybean oil refinery plant ,refined sunflower cooking oil equipment Indutech Machinery Co., ltd (hereafter referred to as "SINODER hot sale soybean oil refinery plant ,refined sunflower cooking oil equipment") is a joint-stock machinery manufacturing enterprise, integrating industrial scientific research, production and marketing. The company is located in the Industry Area Zone of Zhengzhou, China.

FAQ

If you want to know more information , Pls to contact us

Tel: 0371 55933391 Fax: 0371 55919082

Jinan Joysun Machinery Co., Ltd. est une grande entreprise par actions, axée sur la production d'SINODER hot sale soybean oil refinery plant ,refined sunflower cooking oil equipment, intégrée à la recherche scientifique, à la production et aux ventes. La société est située dans la zone industrielle de Shandong salut-technologie, couvre une superficie de 50.000 mètres carrés, avec 15.000 mètres carrés deux standard usine industrielle lourde, plus de 160 ensembles toutes sortes de traitement des métaux de grande et moyenne taille, soudage, équipement d'assemblage .Jinan Joysun Machinery Co., Ltd. attache une grande importance aux échanges techniques et à la coopération internationale, a présenté la technologie de pointe sur et artisanat des États-Unis, Allemagne, Australie et autres pays, établit les lignes de production avancées internationales AAAA et base d'essai moderne de première classe.

Jinan Joysun Machinery Co., Ltd. basé sur une forte résistance technique, l'amélioration des méthodes de détection, excellent système d'assurance qualité pour assurer que « la qualité d'abord, le premier client », responsable de l'installation et la mise en service, les services techniques et des produits de formation technique, après l'installation est terminée je vais 9999999 techniciens vos opérations de production de l'entreprise du personnel de l'équipement de formation professionnelle et technique et des démonstrations en direct.

Contact Us

- Leader Machinery

- Phone(Working Time)

Product Categories

- Flavor coating machine

- cold pressing oil machine

- biodiesel processing machine

- Bird food machine

- Corn flakes machine

- Dog food machine

- Oil Production Line

- animal oil processing equipment

- pet food extruder machine

- Bread crumbs making extruder processing line

- Puff rice snacks machine

- Core-filled snacks machine

- Oil refining equipment

- oil press machine

- fried chips machine

- Breakfast cereals extrusion line

- Cottonseed oil equipment

- japanese rice cake machine

- Soya meat extrusion line

New Products

High Efficiency soybean crude oil refinery equipment

High Efficiency soybean crude oil refinery equipment 50t/d Crude oil refinery, oil extraction equipment for sunflower/peanut/cottonseed/flax oil

50t/d Crude oil refinery, oil extraction equipment for sunflower/peanut/cottonseed/flax oil modular refinery / crude oil refinery equipment / coconut oil refinery

modular refinery / crude oil refinery equipment / coconut oil refinery Mature technology waste essential oil processing refine unit

Mature technology waste essential oil processing refine unit energy saving soybean oil leaching equipment in 2016

energy saving soybean oil leaching equipment in 2016