Home>Products>biodiesel processing machine>2017 high quality professional manufacturer for biodiesel Newly Energymanufacturing biodiesel processing equipment

2017 high quality professional manufacturer for biodiesel Newly Energymanufacturing biodiesel processing equipment

- LD

biodiesel processing machine

- China

- One set 2017 high quality professional manufacturer for biodiesel Newly Energymanufacturing biodiese

- Negotiation

- Within 5 working days

- paypal,UnionPay, Visa/MasterCard, Amex, Discover,T/T

- 158

-

Leader Machinery2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Leader Machinery2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Product Description

2017 high quality professional manufacturer for biodiesel Newly Energymanufacturing biodiesel processing equipment

Product Description

Project Information

What is biodiesel?

Biodiesel is extracted from animal fats,plant oil, waste vegetable oil , used cooking oil , oilseed and widely used for trucks, tractors, ships, etc. It refers to use oil crops, such as soybean, rapeseed, cotton, palm, wild oil plant and engineering micro algae and other aquatic plant oils and animal fats, food waste oil as raw oil material, through ester exchange process , producing a kind of reactivity diesel fuel which could instead of petroleum diesel.

Biodiesel is one kind of biomass energy, and it is a kind of long chain fatty acid monoalkyl esters getting from the biomass utilization technology such as ester exchange. Biodiesel is a mixture of high oxygen content of complex organic compounds, and these compounds are mainly large molecular weight , and including to almost all types of oxygen-containing organic compounds, such as, ether, aldehyde, ketone, phenol, organic acids, alcohols, etc.

Compound biodiesel is extracted from raw material such as abandoned animal fats and pliant oil, used oil and a by-product of oil refinery, added catalyst, synthesized by special equipment and special technology.

What is the advantage of biodiesel?

•Engine is starting at low temperature(-10C).

•It not belongs to dangerous cargo, so it’s easy to transport.

•There is less sulfur and aromatic alkyl in biodiesel, so it's less harmful to human and environment.

•As a kind of renewable energy sources, the biodiesel will not finised.

•The supply of biodiesel is not controlled by OPEC, it’s benefit to the stability of international

petroleum market.

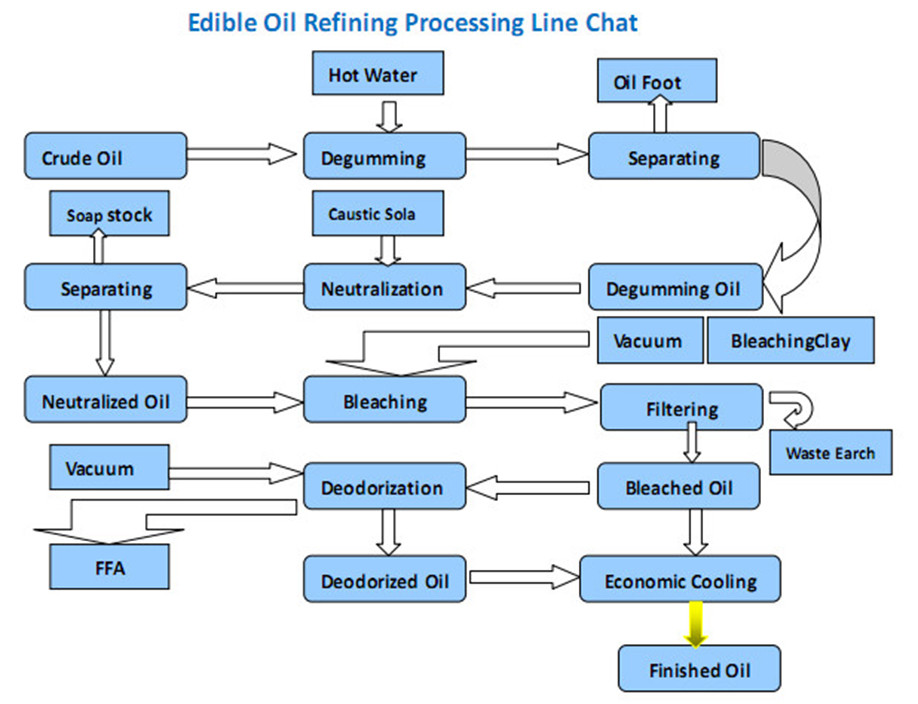

What is the biodiesel processing line?

(1) Physical degumming: first of all, using oil hydration or phosphoric acid-etching method, remove the phospholipids and colloid and other substances, and then preheating, dehydration the oil.

(2) Methanol esterification: adding excess methanol into the raw oil material, with the acid catalyst, conduct pre-esterification, changing free acid into methyl ester.

(3) Continuous ester exchange: the pre-esterification oil together with methyl alcohol, adding little NaOH as catalyst, under a certain temperature and atmospheric pressure, conduct ester exchange, then get methyl ester. Using two-step reaction, through a specially designed separator continuously eliminate the glycerin engendered in the reaction, make the ester exchange continuously.

(4) Gravity precipitation, water washing and stratification.

(5) Glycerol separated from crude methyl ester.

(6) Biodiesel refined

What is the advantages of this processing line?

1. Multi-Feedstock Flexibility

2. Biodiesel of the highest quality

3. Simple process management

4. Low operating costs

What scales do we can do?

Raw material receiving ~ 500t/d

Raw material storage scale ~20000t

Pre-treatment workshop 5~500t /d

Synthetic refining workshop 5~500t /d

What is the byproduct in biodiesel production plant?

Glycerol, plant asphalt.

Company Information

Who are we?

Henan Hi-tech Kingdo Industrial Company Ltd.

Our company is a large-sized joint-equity enterprise which specialize in producing edible oil machanical equipment and it is also a group enterprise integrating scientific research,manufacturing ,sales as one.research institute of machine design company and henan,henan university of technology(formerly the zhengzhou grain college)school-enterprise cooperation in the oil equipment to carry out long-term,protein extraction,phospholipid extraction,etc R&D and application of new technologies.

What is the advantages of our company ?

1. Professional manufacturer of grain and oil machinery over 30 years experience.

2.Completely production line, from raw material to delivery, all are under our control.

3.Quality assured.

4.Certification:CE/BV/ISO

5. Create a good production environment.

6. Perfectly match extraction production line, design different production processes according to different materials.

7. Minimize the total fat loss, increase oil yield and output and improve the quality of oil and cake meal.

What are our main businesses?

1.10-500T/H oil material first cleaning,drying and storage section turn-key project.

2.100-3000 T/D oil pretreatment, shelling and pre-press workshop turnkey project (soybean hot peeling, bean skin crushing; the soybean extrusion, high oil contained pre-press cake extrusion, and high oil contained embryos puffed; of direct puffed). Rice bran production line turn-key project.

3.Leaching workshop turnkey project (Towline extractor, Rotocel extractor, loop type extractor, DTDC separated machine, the full negative pressure evaporation, paraffin wax recovery, leaching workshop degum, phospholipid concentrate).

4.30-1000T/D oil continuous grade two or one physical (chemical) refining production line.

5.20-600T/D sunflower oil, rice bran oil, corn germ oil dewaxing turn-key project

6.10-200T/D Fatty acid esterification production cooking oil production line.

7. 30-1000TPD Biodiesel oil project.

8. 30-1000TPD Biogas project.

9. Wastewater treatment project.

Packaging & Shipping

Packing and Shipping

Standard overseas shipping package employed. eg. plywood case, paper case, etc, which can protect our equipments without hurt and damage.

FAQ

What are common feedstocks used for biodiesel production?

Soybean and rapeseed oil; waste oil including waste vegetable oil and used cooking oil; animal fats, such as tallow and lard, and acid oil.

Why vegetable oil can not be used as fuel ?

Due to its high viscosity and low volatility, when we use vegetable oil as fuel we may meet some problems such as deposition, ring sticking and injector choking in engine.

When we use biodiesel as fuel, can we blend it with petroleum diesel?

Biodiesel can be burnt as fuel directly, it can also be blended with petroleum diesel fuel in any proportion.

What factors may inf2017 high quality professional manufacturer for biodiesel Newly Energymanufacturing biodiesel processing equipmentce the choice of feedstocks?

The vegetable oil’s flash point, viscosity and flow characteristics at low temperatures, energy content, its combustion products and emissions, the cost of feedstocks, including the yield as well as the resources required to grow the oil-bearing plant, the conversion cost, and whether the feedstock may be used for both food and biodiesel production.

Our Services

What can we supply?

Our working team help to install the whole equipments of the plant project for you!

Free services are provided: technical description, equipment configuration quotation list, the volume and weight of equipment, packaging loading, handling consignment.

Paid services are provided: feasibility report, engineering design, plan planning layout, project renderings, equipment manufacturing, spare parts supply, installation and commissioning, training, operation assistance.

If you interested in biogas plant project or mathane making machine please contact me.

Jinan Joysun Machinery Co., Ltd. par l'exploration et la pratique continue, a mis au point un faible investissement, rendement élevé, de faibles coûts d'exploitation, de haute qualité des produits, des avantages de contrôle de facilité d'utilisation, non seulement des avantages « clairvoyante », mais aussi devant le pied.

Jinan Joysun Machinery Co., Ltd. professionnels de R & D de grains entiers, des équipements de raffinage de l'extraction du pétrole, du matériel de raffinage du pétrole partout dans le pays et exportés vers le Vietnam, l'Inde, la Russie, Hong Kong, Taiwan et d'autres endroits. Hong Renbing plus hospitalier pour « l'innovation scientifique, l'intégrité et durable, la qualité première, les services aux doués « philosophie d'entreprise, dédiée à vous fournir pratique, avec des prix compétitifs et de qualité et un service efficace 0,Jinan Joysun Machinery Co., Ltd. plate-forme de test disponible à tout moment Vous êtes invités à prendre les essais et discuter de la coopération!

Contact Us

- Leader Machinery

- Phone(Working Time)

Product Categories

- Flavor coating machine

- cold pressing oil machine

- biodiesel processing machine

- Bird food machine

- Corn flakes machine

- Dog food machine

- Oil Production Line

- animal oil processing equipment

- pet food extruder machine

- Bread crumbs making extruder processing line

- Puff rice snacks machine

- Core-filled snacks machine

- Oil refining equipment

- oil press machine

- fried chips machine

- Breakfast cereals extrusion line

- Cottonseed oil equipment

- japanese rice cake machine

- Soya meat extrusion line

New Products

2-500ton small plant biodiesel processor

2-500ton small plant biodiesel processor recycling waste vegetable oil to biodiesel plant

recycling waste vegetable oil to biodiesel plant biodiesel processing machine making biodiesel fuel for green energy

biodiesel processing machine making biodiesel fuel for green energy Provide After-sales Service for high acid value waste oil to biodiesel processing plant

Provide After-sales Service for high acid value waste oil to biodiesel processing plant Xinxiang Doing Patent design biodiesel processing plant

Xinxiang Doing Patent design biodiesel processing plant