Home>Products>biodiesel processing machine>biodiesel technologies for processing soybean oil to biodiesel production

biodiesel technologies for processing soybean oil to biodiesel production

- LD

biodiesel processing machine

- China

- CE & ISO, SGS

- One set biodiesel technologies for processing soybean oil to biodiesel production

- Negotiation

- 50*15*20

- Within 5 working days

- paypal,UnionPay, Visa/MasterCard, Amex, Discover,T/T

- 172

-

Leader Machinery2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Leader Machinery2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Product Description

What's biodiesel?

Biodiesel is a renewable, clean-burning diesel replacement that is reducing our dependence on foreign petroleum, creating jobs and improving the environment. Made from a diverse mix of feedstocks including recycled cooking oil, soybean oil, and animal fats, it is the first and only EPA-designated Advanced Biofuel in commercial-scale production across the USA and the first to reach 1 billion gallons of annual production. Meeting strict technical fuel quality and engine performance specifications, it can be used in existing diesel engines without modification and is covered by all major engine manufacturers’ warranties, most often in blends of up to 5 percent or 20 percent biodiesel. It is produced at plants in nearly every state in the country in USA.

With less than a decade of commercial-scale production, the industry is proud of its careful approach to growth and strong biodiesel technologies for processing soybean oil to biodiesel production on sustainability. Constantly increased biodiesel production would significantly lessen our dependence on imported oil, bolstering national security and reducing our trade deficit. At the same time, biodiesel’s growth would boost the economy, not just by creating jobs but also by reducing our dependence on global oil markets and vulnerability to price spikes. E.g., the industry in USA is supporting more than 62,000 jobs, generating billions of dollars in GDP, household income and tax revenues. The industry’s economic impact is poised to grow significantly with continued production increases. The industry supports jobs in a variety of sectors, from manufacturing to transportation, agriculture and service.

The EPA has recognized biodiesel’s environmental benefits by classifying it as an Advanced Biofuel, making biodiesel the only commercial-scale fuel produced nationwide to meet the agency’s advanced criteria. According to the EPA, biodiesel reduces greenhouse gas emissions by at least 57 percent and up to 86 percent when compared to petroleum diesel – making it one of the most practical and cost-effective ways to immediately address climate change. In addition, biodiesel sharply reduces major tailpipe pollutants from petroleum diesel, particularly from older diesel vehicles. This is important because the EPA has consistently cited diesel exhaust – primarily from older trucks, buses and other vehicles – as one of the nation's most dangerous pollutants.

Biodiesel is produced using a broad variety of resources. This diversity has grown significantly in recent years, helping shape a nimble industry that is constantly searching for new technologies and feedstocks. In fact, industry demand for less expensive, reliable sources of fats and oils is stimulating promising research on next-generation feedstocks such as algae and camelina.

What's the Applications ?

Biodiesel can be used in pure form (B100) or may be blended with petroleum diesel at any concentration in most injection pump diesel engines.

1. Distribution

Since the passage of the Energy Policy Act of 2005, biodiesel use has been increasing in the United States. In the UK, the Renewable Transport Fuel Obligation obliges suppliers to include 5% renewable fuel in all transport fuel sold in the UK by 2010. For road diesel, this effectively means 5% biodiesel (B5).

2. Vehicular use and manufacturer acceptance

In 2005, Chrysler (then part of DaimlerChrysler) released the Jeep Liberty CRD diesels from the factory into the American market with 5% biodiesel blends, indicating at least partial acceptance of biodiesel as an acceptable diesel fuel additive. In 2007, DaimlerChrysler indicated its intention to increase warranty coverage to 20% biodiesel blends if biofuel quality in the United States can be standardized.

The Volkswagen Group has released a statement indicating that several of its vehicles are compatible with B5 and B100 made from rape seed oil and compatible with the EN 14214 standard. The use of the specified biodiesel type in its cars will not void any warranty.

In 2007, McDonalds of UK announced it would start producing biodiesel from the waste oil byproduct of its restaurants. This fuel would be used to run its fleet.

The 2014 Chevy Cruze Clean Turbo Diesel, direct from the factory, will be rated for up to B20 (blend of 20% biodiesel / 80% regular diesel) biodiesel compatibility

3. Railway usage

British train operating company Virgin Trains claimed to have run the UK's first "biodiesel train", which was converted to run on 80% petrodiesel and 20% biodiesel.

4. Aircraft use

A test flight has been performed by a Czech jet aircraft completely powered on biodiesel.

5. Cleaning oil spills

With 80-90% of oil spill costs invested in shoreline cleanup, there is a search for more efficient and cost-effective methods to extract oil spills from the shorelines. Biodiesel has displayed its capacity to significantly dissolve crude oil, depending on the source of the fatty acids.

6. Biodiesel in generators

In 2001, UC Riverside installed a 6-megawatt backup power system that is entirely fueled by biodiesel. Backup diesel-fueled generators allow companies to avoid damaging blackouts of critical operations at the expense of high pollution and emission rates. By using B100, these generators were able to essentially eliminate the byproducts that result in smog, ozone, and sulfur emissions. The use of these generators in residential areas around schools, hospitals, and the general public result in substantial reductions in poisonous carbon monoxide and particulate matter.

7. As a heating oil

Biodiesel can also be used as a heating fuel in domestic and commercial boilers, a mix of heating oil and biofuel which is standardized and taxed slightly differently from diesel fuel used for transportation. It is sometimes known as "bioheat" (which is a registered trademark of the National Biodiesel Board [NBB] and the National Oilheat Research Alliance [NORA] in the U.S., and Columbia Fuels in Canada). Heating biodiesel is available in various blends. ASTM 396 recognizes blends of up to 5 percent biodiesel as equivalent to pure petroleum heating oil. Blends of higher levels of up to 20% biofuel are used by many consumers.

Why should I use biodiesel?

Biodiesel is better for the environment because it is made from renewable resources and has lower emissions compared to petroleum diesel. It is less toxic than table salt and biodegrades as fast as sugar. Produced domestically with natural resources, its use decreases our dependence on imported fuel and contributes to our own economy.

What's the raw material for biodiesel?

1. Vegetable oils

- Castor oil, lower cost than many candidates. Kinematic viscosity may be an issue.

- Coconut oil (copra oil), promising for local use in places that produce coconuts.

- Colza oil, from Brassica rapa, var. oleifera (turnip) is closely related to rapeseed (or canola) oil. It is a major source of biodiesel in Germany.

- Corn oil, appealing because of the abundance of maize as a crop.

- Cottonseed oil, the subject of study for cost-effectiveness as a biodiesel feedstock.

- False flax oil, from Camelina sativa, used in Europe in oil lamps until the 18th century.

- Hemp oil, relatively low in emissions. Production is problematic in some countries because of its association with marijuana.

- Mustard oil, shown to be comparable to Canola oil as a biofuel.

- Palm oil, very popular for biofuel, but the environmental impact from growing large quantities of oil palms has recently called the use of palm oil into question.

- Peanut oil, used in one of the first demonstrations of the Diesel engine in 1900.

- Radish oil. Wild radish contains up to 48% oil, making it appealing as a fuel.

- Rapeseed oil, the most common base oil used in Europe in biodiesel production.

- Ramtil oil, used for lighting in India.

- Rice bran oil, appealing because of lower cost than many other vegetable oils. Widely grown in Asia.

- Safflower oil, explored recently as a biofuel in Montana.

- Salicornia oil, from the seeds of Salicornia bigelovii, a halophyte (salt-loving plant) native to Mexico.

- Soybean oil, not economical as a fuel crop, but appealing as a byproduct of soybean crops for other uses.

- Sunflower oil, suitable as a fuel, but not necessarily cost effective.

- Tigernut oil has been described by researchers in China as having "great potential as a biodiesel fuel."

- Tung oil, referenced in several lists of vegetable oils that are suitable for biodiesel. Several factors in China produce biodiesel from tung oil.

2. Animal fats

Animal fats including tallow, lard, yellow grease, chicken fat, and the by-products of the production of Omega-3 fatty acids from fish oil.

3. Animal and vegetable oil mixture

4. Waste oil

Waste cooking oil, illegal cooking oil, hogwash oil and so on.

What's the biodiesel plant?

Process biodiesel from vegetable oils, animal fats, and waste/used cooking oil through a chemical process. With annual capacity growing every year, biodiesel plants are an important part of our energy future. As biodiesel use and demand has grown, so too has the number of plants and the diversity of every locations.

What's the technical standards of biodiesel?

| Items | Value | |

| Density(20℃)/(KG/M³) | 820-900 | |

| Kinematic viscosity(20℃)/mm²/S) | 3.0-8.0 | |

| Closed-cup flash point (℃) | ≥ | 130 |

| Cold filter plugging point (℃) | ≤ | |

| Sulphur content (%) | ≤ | 0.05% |

| Carbon residue on 10% residuum (%) | ≤ | 0.3 |

| Sulfated Ash (%) | ≤ | 0.02 |

| Moisture (%) | ≤ | water mark |

| Mechanical impurities | No | |

| Copper corrosion | ≤ | Level 1 |

| Cetane number | ≥ | 49 |

| Oxidation stability(110℃)/ h | ≥ | 6/Addtives |

| Acid value(mgKOH/g) | ≤ | 0.8 |

| Free glycerol content (%) | ≤ | 0.02 |

| Total glycerin content (%) | ≤ | 0.24 |

| 90% recovered temperature (℃) | ≤ | 360 |

What's the advantage?

1. Waste management for recycling waste oil to biodiesel.

2. Biodiesel can be used in any diesel engine in pure form or blended with petroleum diesel at any level.

3. Even a blend of 20% biodiesel and 80% petroleum diesel will significantly reduce carcinogenic emissions and gases that may contribute to global warming.

4. Glycerin is the byproduct of the biodiesel production process, and can be used in personal care products or a variety of chemical applications.

Per a recent market study, the production and use of biodiesel fuel promises to bring $24 billion to the U.S. economy between 2005 and 2015, assuming biodiesel growth reaches 650 million gallons of annual production per year by 2015.1 This study also projected:

• Biodiesel production will create 39,102 new jobs in all sectors of the economy.

• Additional tax revenues from biodiesel production will more than pay for the federal tax incentives provided to the industry, keeping $13.6 billion in the U.S. that would otherwise be spent on foreign oil.

What's the process for biodiesel production?

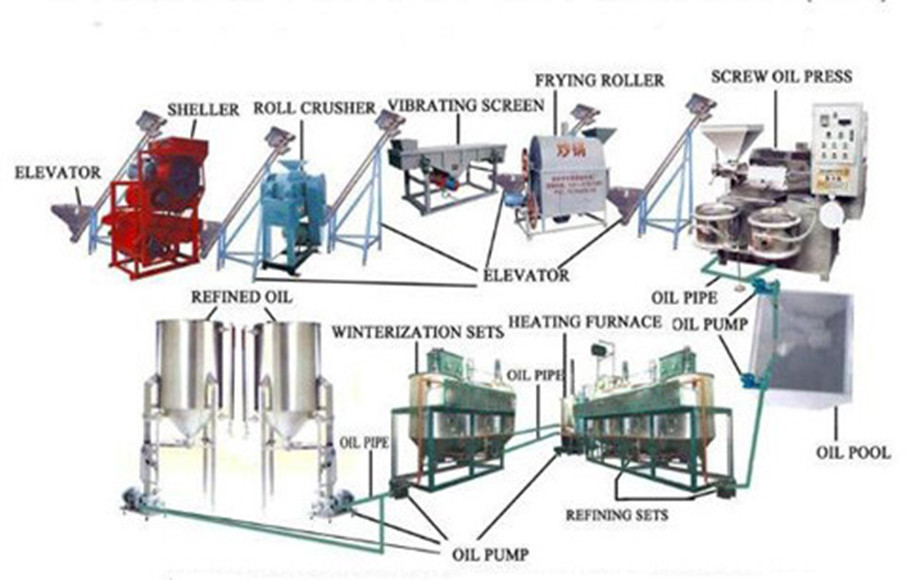

What's the biodiesel plant looks like?

Who we are?

Henan DOING Mechanical Equipment Co.,ltd is a biodiesel technologies for processing soybean oil to biodiesel production manufacturer specialized in large and medium-sized oil-related machineries, including waste tire/plastic/rubber to fuel oil pyrolysis machine, waste oil(black oil) refinery machine to get diesel oil, cooking oil production line as well as biodiesel production line.

Our business is related to diesel oil and cooking oil industry. We provide the turn-key project for a variety of edible oil pretreatment, pre-pressing, extraction, refining, fractionation and by-products further processing; bio-diesel production, waste tire pyrolysis machine and by-product oil further processing oil refinery machine, including equipment design, process design, power distribution design, instrument control design, civil construction design, installation and commissioning,etc.

Our oil project has been set up in 23 foreign countries and regions in the world and achieve a good customer reputation.

DOING is always trying to serve customers well by providing highest quality products and best after sales service. We are doing at any time.

What can we do for you?

1. Provide you the high quality biodiesel plant with the best raw materials and the unique technology.

2. Professionally explain your questions and service warm thorough.

3. After service provided and engineers available to overseas help you with the installation and commisssioning of the biodiesel plant.

4. One year warranty for free.

What can make you believe us?

1. We have 9 years experiences in the machinery market, 5 years domestic trade, 4 years freign trade.

2. Exported to almost 30 countries, have customers all over the world.

3. Certificated by ISO, CE, SGS, BV, TUV, EPA

Jinan Joysun Machinery Co., Ltd. par l'exploration et la pratique continue, a mis au point un faible investissement, rendement élevé, de faibles coûts d'exploitation, de haute qualité des produits, des avantages de contrôle de facilité d'utilisation, non seulement des avantages « clairvoyante », mais aussi devant le pied.

Jinan Joysun Machinery Co., Ltd. professionnels de R & D de grains entiers, des équipements de raffinage de l'extraction du pétrole, du matériel de raffinage du pétrole partout dans le pays et exportés vers le Vietnam, l'Inde, la Russie, Hong Kong, Taiwan et d'autres endroits. Hong Renbing plus hospitalier pour « l'innovation scientifique, l'intégrité et durable, la qualité première, les services aux doués « philosophie d'entreprise, dédiée à vous fournir pratique, avec des prix compétitifs et de qualité et un service efficace 0,Jinan Joysun Machinery Co., Ltd. plate-forme de test disponible à tout moment Vous êtes invités à prendre les essais et discuter de la coopération!

Contact Us

- Leader Machinery

- Phone(Working Time)

Product Categories

- Flavor coating machine

- cold pressing oil machine

- biodiesel processing machine

- Bird food machine

- Corn flakes machine

- Dog food machine

- Oil Production Line

- animal oil processing equipment

- pet food extruder machine

- Bread crumbs making extruder processing line

- Puff rice snacks machine

- Core-filled snacks machine

- Oil refining equipment

- oil press machine

- fried chips machine

- Breakfast cereals extrusion line

- Cottonseed oil equipment

- japanese rice cake machine

- Soya meat extrusion line

New Products

2-500ton small plant biodiesel processor

2-500ton small plant biodiesel processor recycling waste vegetable oil to biodiesel plant

recycling waste vegetable oil to biodiesel plant biodiesel processing machine making biodiesel fuel for green energy

biodiesel processing machine making biodiesel fuel for green energy Provide After-sales Service for high acid value waste oil to biodiesel processing plant

Provide After-sales Service for high acid value waste oil to biodiesel processing plant Xinxiang Doing Patent design biodiesel processing plant

Xinxiang Doing Patent design biodiesel processing plant