Home>Products>Cottonseed oil equipment>New technology cottonseed prepressed cake solvent extraction machine

New technology cottonseed prepressed cake solvent extraction machine

- LD

Cottonseed oil equipment

- China

- ISO CE

- One set New technology cottonseed prepressed cake solvent extraction machine

- Negotiation

- 12.3*2.9*12 M

- Within 5 working days

- paypal,UnionPay, Visa/MasterCard, Amex, Discover,T/T

- 71

-

Leader Machinery2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Leader Machinery2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Product Description

New technology cottonseed prepressed cake solvent extraction machine

Product Description

Craft flow for oil extraction workshop:

solvent steam

↓ ↓

extraction → mixed oil → evaporation → steam-stripping → crude oil

Cottonseed oil extraction plant main parts includes:

(1)Solvent pumps: continuously spray solvent to the rotary-type extractor

(2)Roary extractor: Spray and soak the pre-pressed cake with solvent so that oil fats can be dissolved in solvent(form miscella). After processing, you can get wet meal and micella (mixed oil).

(3)DTDC: Used to separate the solvent from the wet meal.

(4)Miscellanous tank 1st: pump the miscella (oil with solvent) in to the miscella 1st , and then add 10% saline water to it.The phospholipid and impurities in the miscella will react with the saline water, at last the reactant precipitate, reaching the goal of purifying.

(5)Miscella tank 2nd: the purified miscella will be pumped into it.

(6)Miscella stripping: it will remove the remaining solvent in miscella. And the solvent will be discharged to condenser for recycling.

(7)Condensers: used to cooling the solvent gas separated from the wet meal and miscella for recycling.

Advantages of extraction craft:

1.Process design of our cottonseed protein dephenolization machine is reasonable and compact,it meets international

2.advanced technology standard,and owns automatic,continuous and machanized production conditions.

3.High oil yield, low residual oil in meal

4.Low labor intensity

5.Good working environment

6.Good meal quality.

Damp-proof packing for motors

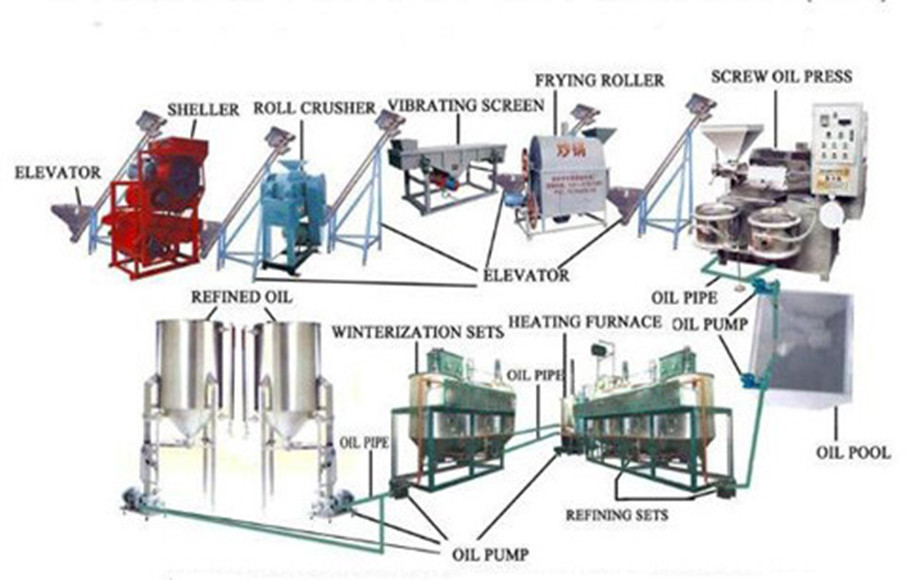

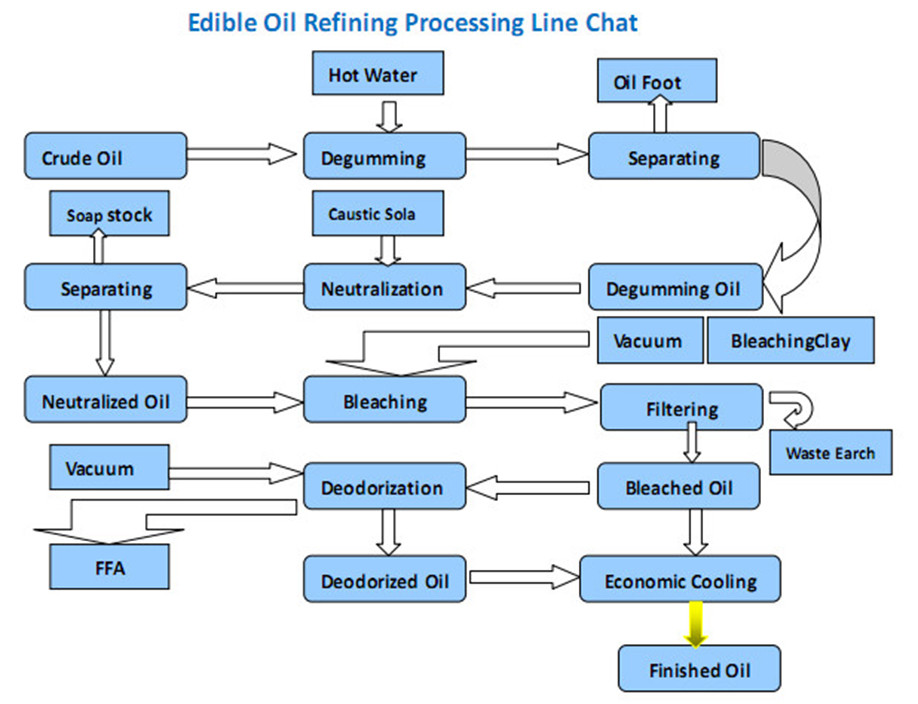

mini cooking oil refining plant ,small scale oil refinery machine ,mini crude oil refinery

Delivery Time: Shipped in 45 days after payment

Henan Hanson Machinery Co., ltd. is a domestic and foreign oil equipmentengineering

contractor, is a collection r & d, design, manufacturing, general contracting of an integrated entity enterprises, business covers grain and oil machinery, chemical equipment, feed machinery, environmental machinery , pressure vessels, mechanical and electrical equipment design, manufacture, installation, commissioning, personnel training and other fields.

1.Do you supply engineers to install the machine and train our workers ?

Sure, we are the manufacturer, we supply turn-key project line for our customer.

Our engineer will give your workers free training .

2.Do you supply after sales service and how you guarantee you have the ability and the quality ?

We are big company .we are manufacturer , not trade company .We offer one year guarantee time for your machine .

Looing forward for your enquiry! Welcome to our factory!!!

Jinan Joysun Machinery Co., Ltd. toujours adhérer à l'utilisateur de faire une conception minutieuse des exigences de qualité des produits, offrent des solutions spécifiques, la fabrication de précision après consensus.Jinan Joysun Machinery Co., Ltd. par l'exploration et la pratique continue, a mis au point un faible investissement, rendement élevé, de faibles coûts d'exploitation, de haute qualité des produits, des avantages de contrôle de facilité d'utilisation, non seulement des avantages « clairvoyante », mais aussi devant le pied.

New technology cottonseed prepressed cake solvent extraction machine Les transformateurs d'huile de noix de coco conventionnels utilisent de l'hexane comme solvant pour extraire jusqu'à 10% d'huile de plus que ce qui est produit avec seulement des broyeurs rotatifs et des expulseurs. New technology cottonseed prepressed cake solvent extraction machine puis raffiner l'huile pour éliminer certains acides gras libres afin de réduire la susceptibilité à la rancidification. D'autres procédés pour augmenter la durée de conservation comprennent l'utilisation de coprah avec une teneur en humidité inférieure à 6%, la teneur en humidité de l'huile inférieure à 0,2%, chauffe l'huile à 130-150 ° C (266-302 ° F) et l'ajout de sel ou d'acide citrique .

Contact Us

- Leader Machinery

- Phone(Working Time)

Product Categories

- Flavor coating machine

- cold pressing oil machine

- biodiesel processing machine

- Bird food machine

- Corn flakes machine

- Dog food machine

- Oil Production Line

- animal oil processing equipment

- pet food extruder machine

- Bread crumbs making extruder processing line

- Puff rice snacks machine

- Core-filled snacks machine

- Oil refining equipment

- oil press machine

- fried chips machine

- Breakfast cereals extrusion line

- Cottonseed oil equipment

- japanese rice cake machine

- Soya meat extrusion line

New Products

Centrifugal machine used crude oil refinery for sale

Centrifugal machine used crude oil refinery for sale 2015 sunflower / rapeseed / cotton / soybean edible oil refinery / crude oil refinery machine

2015 sunflower / rapeseed / cotton / soybean edible oil refinery / crude oil refinery machine First manufacturer successfully make olive palm kernel oil refinery

First manufacturer successfully make olive palm kernel oil refinery Automatic continuous type moringa seed edible oil refinery plant

Automatic continuous type moringa seed edible oil refinery plant 10% discount small scale refining machine edible oil refinery

10% discount small scale refining machine edible oil refinery